Hydrogen is often called the “fuel of the future,” and for good reason—it’s clean, versatile, and can replace fossil fuels in industries that are hard to decarbonize, such as steelmaking and heavy transport.

But producing hydrogen in a green and affordable way has remained a challenge.

Now, researchers in China have taken a major step toward solving this problem with a new kind of electrode that makes hydrogen cheaper to produce and easier to scale up for industry.

A team led by Professor Zhao Shenlong at the National Center for Nanoscience and Technology of the Chinese Academy of Sciences has developed advanced electrodes made from metal-organic frameworks, or MOFs.

These are highly porous materials that can be engineered at the molecular level.

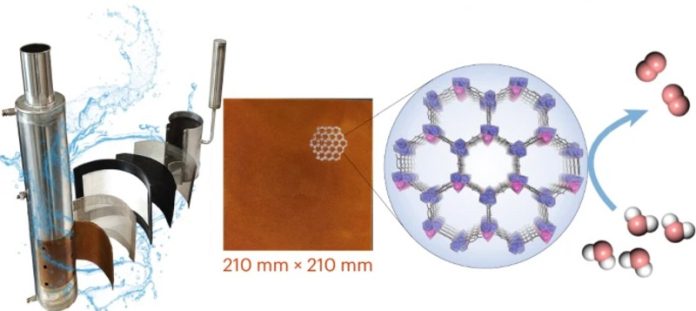

The researchers designed the electrodes for alkaline water electrolysis, a process that uses electricity—ideally from renewable sources like wind or solar—to split water into hydrogen and oxygen.

One of the main hurdles in water electrolysis is the oxygen evolution reaction, which is slow and energy-intensive.

Traditional electrodes that drive this reaction tend to be costly, inefficient, or difficult to produce at large scale. The new MOF electrodes, however, overcome these barriers thanks to two innovations.

First, the team used ultrasonication to produce MOF powders in kilogram-scale quantities, ensuring the process is industrially practical.

Second, they employed a simple room-temperature method called electrodeposition to create large-area electrodes ready for use in real electrolysis systems.

The results were striking. Integrated into alkaline electrolysis setups, the MOF electrodes achieved very low energy consumption—just 4.11 kilowatt-hours per cubic meter of hydrogen—while maintaining stable performance for more than 5,000 hours.

Their impressive efficiency is linked to the clever use of cerium doping, which adjusts the electronic structure of cobalt active sites in the MOFs. This speeds up the sluggish oxygen reaction, while the material’s distorted lattice and huge surface area improve the flow of water, gases, and electrolytes.

Even more exciting is the cost advantage. The electrodes enabled hydrogen production at just $2.71 per kilogram, a price point that brings green hydrogen closer to competing with fossil fuels. According to the researchers, this makes their technology not only scientifically promising but also commercially viable.

The work, published in Nature Chemical Engineering, could help reshape the global energy landscape.

While further optimization is needed to ensure consistent quality at even larger scales, the study shows that MOF-based electrolysis systems may finally provide the breakthrough the world needs to make hydrogen a mainstream clean energy source.