A major breakthrough from German scientists is helping robots do something that once seemed impossible: quickly recognize transparent, shiny, or jet-black objects.

Thanks to a new system called goROBOT3D, developed by researchers at the Fraunhofer Institute for Applied Optics and Precision Engineering (IOF), machines can now “see” these hard-to-detect surfaces in under two seconds—a huge leap from the 15 seconds it used to take.

While these objects may be easy for the human eye to spot, they pose a big challenge for robots.

Traditional cameras and sensors often fail when dealing with materials like clear glass, polished metal, or deep black plastic, which either reflect light too well or not at all.

But the new goROBOT3D system uses a smart thermal imaging method that allows robots to spot and understand the 3D shape of these tricky items almost instantly.

The key to this fast and accurate detection is a new type of thermal projection technique. Instead of taking hundreds of pictures like older systems, goROBOT3D uses what’s called “single-shot” technology.

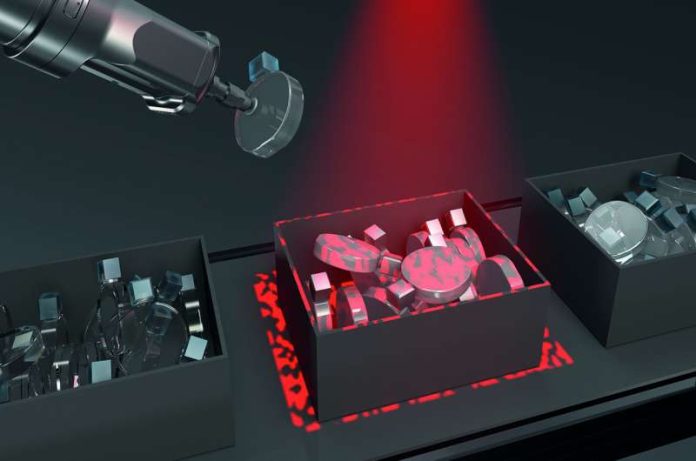

Here’s how it works: the surface of the object is gently heated in a special way that creates a thermal pattern. This pattern is captured by two thermal cameras at the same time. From just this one image pair, the system can reconstruct a full 3D model of the object.

To project the pattern, the researchers used tiny optical tools called diffractive optical elements (DOEs). These split a laser beam into many dots, which are then scattered across the object’s surface. This makes the entire process faster, more efficient, and accurate—even with objects that are clear or dark.

Once the 3D data is captured, artificial intelligence steps in. It analyzes the shape of the object and quickly tells a robot arm where and how to pick it up. This process, known as “bin picking,” helps robots grab items from messy environments, like random parts in a box.

Because goROBOT3D works so fast, it allows manufacturing processes to run more smoothly. While one object is being picked up, the system can already be scanning the next one. This leads to more continuous and efficient production lines with fewer delays.

The flexible design of the system means it can be used in many different industries, from product design to smart factories.

Fraunhofer IOF will debut the technology at the automatica trade show in Munich this June, where visitors can see how it could transform robotic vision in the real world.

Source: KSR.