A technology used to make instant coffee is now helping scientists create better and more eco-friendly batteries.

Researchers from the Korea Electrotechnology Research Institute (KERI) and the Korea Institute of Materials Science (KIMS) have used spray drying—commonly used in the food and pharmaceutical industries—to improve how battery electrodes are made.

Their breakthrough could lead to stronger, higher-capacity batteries.

Battery electrodes store and deliver electricity using a mix of materials: active materials that hold energy, conductive additives that help move the electricity, and binders that hold everything together.

There are two main ways to mix these ingredients: a wet process that uses solvents, and a dry process that uses no liquids.

The dry method is better for the environment and could lead to batteries with higher energy density. However, it’s been hard to get the materials to mix evenly without using a liquid.

To solve this, the team borrowed a trick from how instant coffee is made.

In that process, liquid coffee is sprayed into hot air, and the water evaporates instantly, leaving dry coffee powder. The researchers used a similar method.

First, they mixed the active materials and conductive additives in liquid form, then sprayed this mixture into a hot chamber. The heat quickly removed the liquid, leaving behind a well-mixed dry powder.

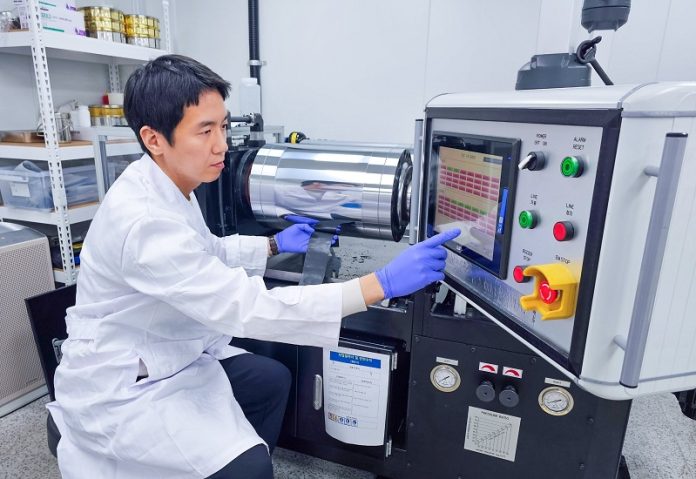

This powder was then turned into electrodes. At KERI, the researchers added binders and used a process called fibrillation to stretch the binders into tiny threads, which helped connect everything more evenly.

Finally, they used a technique called calendering to press the mixture into a thin, flat film—creating the finished electrode.

This new method resulted in electrodes with a higher percentage of active materials—up to 98%, which is one of the best results in the world. It also reduced the amount of conductive additives needed to as little as 0.1%, far lower than the usual 2–5%. With more room for active materials, the battery can store more energy.

The new electrodes reached an energy capacity of about 7 milliampere-hours per square centimeter, which is almost double what commercial batteries offer today.

The scientists believe this technique could help make more efficient batteries for the future, including for solid-state and lithium-sulfur batteries. They also hope to make the production process cheaper and more scalable, so the technology can be used in real-world applications soon.

By mixing materials better and using less harmful chemicals, this coffee-inspired method could play a key role in the next generation of green, high-performance batteries.