Stretchable technology is becoming a game-changer in electronics, enabling devices to bend, stretch, and even twist while still working perfectly.

This exciting field has led to innovations like flexible displays, sensors, electronic skin, smart clothing, and soft robots.

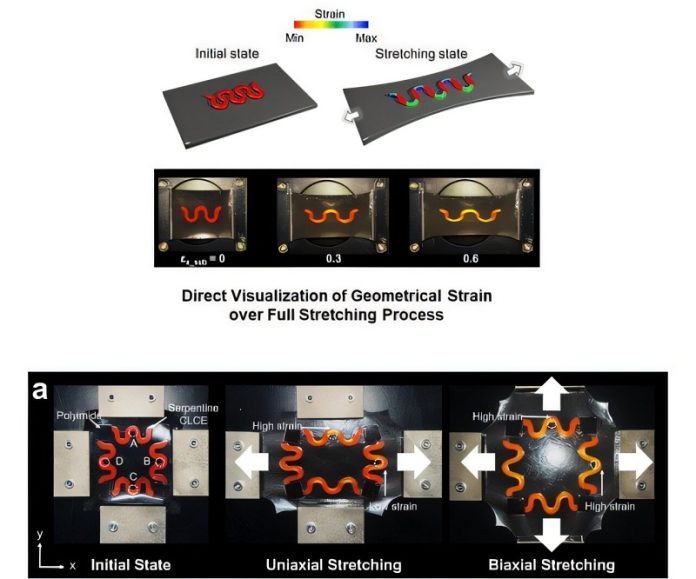

But understanding how these stretchable materials deform under stress has been a challenge—until now.

Researchers at POSTECH (Pohang University of Science and Technology) have developed a groundbreaking system that allows scientists to see, in real-time, how critical components of stretchable technology—called serpentine structures—change shape.

Led by Professor Su Seok Choi and a team of graduate students, their study was published in the journal Advanced Science.

Stretchable electronics often rely on “serpentine interconnects.” These are wave-shaped, elastic connections that link rigid electronic parts, such as semiconductors, sensors, and displays.

They allow otherwise inflexible materials to stretch without breaking, making them essential for creating truly flexible devices.

Until now, researchers could only study these serpentine structures after they had been stretched to the point of breaking.

This meant they relied heavily on theoretical simulations or incomplete data from previous stretching cycles. Without a way to see the changes in real-time, it was difficult to design better and more reliable structures.

The POSTECH team solved this problem using a special material called Chiral Liquid Crystal Elastomer (CLCE).

This material is “mechanochromic,” meaning it changes color when stretched. By applying CLCE to serpentine structures, the researchers created a system that visually shows how the structures deform. As the serpentine connections stretch, the material shifts colors, making the process easy to monitor in real-time.

This color-based visualization provides immediate feedback on how the structures handle stress and deform, offering insights that were previously impossible to gain. The team also confirmed their findings through computer simulations using finite element analysis, ensuring their results were accurate and reliable.

This new technology could significantly speed up the development of stretchable electronics.

Previously, creating and testing stretchable devices required complex nanofabrication processes and long trial-and-error cycles. Now, researchers can directly observe and optimize serpentine structures in real-time, saving time and resources.

Professor Choi explained, “Our research allows for precise evaluation and design of the connections at the heart of stretchable technology.”

The potential applications are vast. From more durable flexible displays to better-performing electronic skin for prosthetics, this innovation could accelerate the commercialization of stretchable devices across industries.

By making it easier to understand and improve the design of stretchable materials, this breakthrough opens the door to faster advancements in technologies like wearable health monitors, biomimetic robots, and smart clothing.

The ability to visualize deformation in real time is a major step forward, allowing scientists and engineers to create devices that are both more reliable and versatile.

With their innovative approach, the POSTECH team has not only advanced our understanding of stretchable materials but also laid the groundwork for exciting new possibilities in the world of flexible electronics.

Source: KSR.