In the world of batteries, there’s a big leap forward thanks to a team of scientists led by Professor Seok Ju Kang at UNIST (Ulsan National Institute of Science and Technology).

They’ve figured out a smarter way to make a key ingredient for batteries called polymer solid electrolytes.

This ingredient is super important because it helps batteries work better and last longer. Their groundbreaking work was shared in a scientific journal called Energy Storage Materials.

Traditionally, making these electrolytes was a bit like making a fancy chocolate bar, melting things down and hoping they set just right.

But this team thought outside the box and borrowed a page from how people make iron pipes.

Yes, you heard right, iron pipes!

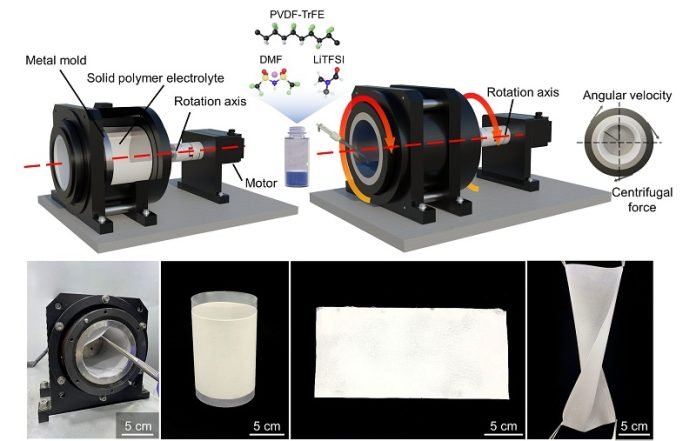

They used something called a horizontal centrifugal casting method. Imagine spinning the liquid ingredients really fast in a horizontal tube, sort of like spinning pizza dough, to get a perfectly even layer.

This clever twist not only saves a ton of the stuff they need to make the electrolytes but also bumps up the battery’s quality and power. Professor Kang said it’s like taking the old iron pipe method and supercharging it for battery making.

What’s really cool is that this new way is super quick – 13 times faster than before! They don’t have to wait around for things to dry or cook in a vacuum oven, which was a big slowdown in the old process.

Plus, they can make lots of it at once by changing the size of their spinning tube, making sure every batch is just as good as the last.

Hyunwoo Kim, a key member of the team, mentioned that this new method doesn’t just speed things up; it actually makes the batteries work better and last longer without having to mess with the recipe.

By skipping the slow, energy-hogging steps like vacuum heat treatment, they’ve made it a lot easier and cheaper to mass-produce these essential battery parts.

This breakthrough could mean more reliable and efficient batteries for everything from your smartphone to electric cars, making our tech-hungry lives a little easier and greener.

Thanks to Professor Kang and his team’s innovative thinking, the future of batteries is looking brighter, faster, and more efficient than ever.

The study was published in the journal Energy Storage Materials.