Lithium is a crucial element used in rechargeable batteries for many technologies, including smartphones, medical devices, and electric vehicles.

As these technologies become more popular, the demand for lithium continues to rise.

Traditionally, lithium is extracted from two main sources: underground water called brines and a type of rock known as spodumene.

The typical method to extract lithium from brines involves letting water evaporate under the sun, which is quite slow and requires a lot of water.

On the other hand, getting lithium from spodumene involves heating the rock at very high temperatures, which uses a lot of energy and can harm the environment by producing greenhouse gases and toxic waste.

To address these challenges, scientists at the Critical Materials Innovation (CMI) Hub, led by the U.S. Department of Energy’s Ames National Laboratory, have developed a new technique.

They’re using a special kind of chemistry called mechanochemistry, which involves grinding and shaking solid substances to start chemical reactions. This approach is not only more environmentally friendly but also faster and less wasteful.

The leader of the project, Ihor Hlova, along with his team, has created a process known as mechanochemical extraction of lithium at low temperatures, or MELLT.

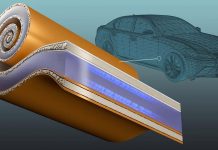

This process uses a technique called ball milling, where chunks of spodumene and a chemical called sodium carbonate are placed in a chamber with steel balls.

The chamber shakes vigorously, causing the materials to collide and react, forming a lithium compound that dissolves in water. The lithium can then be easily extracted by washing the mixture with water.

This new method, MELLT, is a big improvement over traditional methods. It significantly reduces energy use, speeds up the process, and avoids creating harmful waste.

Tyler Del Rose, a postdoctoral researcher and team member, emphasizes that mechanochemistry is generally underused in extraction processes.

However, its ability to cause chemical reactions by creating small defects on the surfaces of solids makes it very effective.

The development of MELLT is part of a larger effort by CMI to find new and better ways to extract lithium.

This project involves several national labs, universities, and industrial partners working together.

Tom Lograsso, the director of CMI, highlights that their mission is to develop innovative solutions to supply chain challenges, providing U.S. industries with new technologies ready for commercial use.

This new approach not only promises to make lithium extraction more sustainable but also helps ensure a steady supply of this essential element, supporting the growth of clean energy technologies.

Source: Ames National Laboratory.