Penn State researchers led by assistant professor Hongtao Sun have developed an innovative method for fabricating battery electrodes.

This new approach could lead to high-performance batteries with higher energy capacity, reduced weight, and improved energy efficiency.

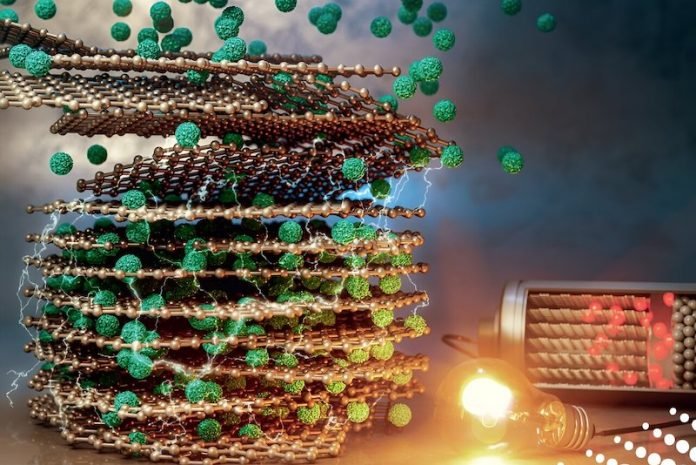

Their work focuses on maximizing the percentage of active components in batteries by making thicker and denser electrodes, thus enhancing both the gravimetric and volumetric performance of batteries.

The research has been published in the journal Carbon and points towards significant advancements in battery technology for electric vehicles (EVs) and other applications.

The Need for Better Batteries

As electric vehicles become increasingly popular, there is a pressing need for more efficient, lighter, and faster-charging batteries.

The existing lithium-ion batteries have limitations in energy density and safety, which are hurdles to mass adoption of electric cars.

Sun’s Approach: Focusing on Electrodes

Hongtao Sun and his team propose that the key to improving battery performance lies in the electrodes, which are the active components in batteries.

Currently, a significant percentage of a battery’s weight comes from passive components like packaging and separators, which do not contribute to the battery’s performance.

By making electrodes thicker and denser, Sun believes that the overall performance of electric vehicles can be enhanced due to a higher percentage of active components and reduced weight of the battery package.

Overcoming Technical Challenges

Normally, thicker electrodes would lead to poor charge transport kinetics, affecting the overall battery performance.

To tackle this, the team applied Spark Plasma Sintering (SPS), a method that compacts and densifies materials using heat and pressure.

This led to electrodes that are up to five times thicker than conventional ones, allowing for greater energy storage and fast charge transport.

The Benefits

Higher Energy Capacity: Thicker electrodes allow for more space to store energy, increasing the overall energy capacity of the battery.

Reduced Weight: With a higher percentage of active components, the overall weight of the battery package can be reduced, making EVs more efficient.

Faster Charging: The SPS technique enables faster charge transport, potentially reducing the time needed to charge the battery.

Future Outlook

The next step is to develop a scalable manufacturing process for these innovative electrodes.

The team is also exploring how to integrate these batteries into the vehicle structure, such as incorporating them into the car’s roof, to further reduce weight and maximize space.

Conclusion

This groundbreaking research from Penn State has the potential to revolutionize battery technology, offering a pathway to more efficient, lighter, and faster-charging batteries.

These advancements could significantly impact the electric vehicle industry, bringing us closer to a more sustainable and efficient transportation future.

The study was published in Carbon.

Follow us on Twitter for more articles about this topic.

Source: Pennsylvania State University