Researchers have identified a potential new degradation mechanism for electric vehicle batteries – a key step to designing effective methods to improve battery lifespan.

The researchers, from the Universities of Cambridge and Liverpool, and the Diamond Light Source, have identified one of the reasons why state-of-the-art ‘nickel-rich’ battery materials become fatigued, and can no longer be fully charged after prolonged use.

Their results, reported in the journal Nature Materials, open the door to the development of new strategies to improve battery lifespans.

As part of efforts to combat climate change, many countries have announced ambitious plans to replace petrol or diesel vehicles with electric vehicles (EVs) by 2050 or earlier.

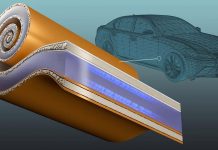

The lithium-ion batteries used by electric vehicles are likely to dominate the electric vehicle market for the foreseeable future, and nickel-rich lithium transition-metal oxides are the state-of-the-art choice for the positive electrode, or cathode, in these batteries.

Currently, most electric vehicle batteries contain significant amounts of cobalt in their cathode materials. However, cobalt can cause severe environmental damage, so researchers have been looking to replace it with nickel, which also offers higher practical capacities than cobalt.

However, nickel-rich materials degrade much faster than existing technology and require additional study to be commercially viable for applications such as electric vehicles.

“Unlike consumable electronics which typically have lifetimes of only a few years, vehicles are expected to last much longer and therefore it is essential to increase the lifetime of an electric vehicle battery,” said Dr Chao Xu from Cambridge’s Department of Chemistry, and the first author of the article.

“That’s why a comprehensive, in-depth understanding of how they work and why they fail over a long time is crucial to improving their performance.”

To monitor the changes of the battery materials in real time over several months of battery testing, the researchers used laser technology to design a new coin cell, also known as button cell.

“This design offers a new possibility of studying degradation mechanisms over a long period of cycling for many battery chemistries,” said Xu.

During the study, the researchers found that a proportion of the cathode material becomes fatigued after repetitive charging and discharging of the cell, and the amount of the fatigued material increases as the cycling continues.

Xu and his colleagues dived deep into the structure of the material at the atomic scale to seek answers as to why such fatigue process occurs.

“In order to fully function, battery materials need to expand and shrink as the lithium ions move in and out,” said Xu. “However, after prolonged use, we found that the atoms at the surface of the material had rearranged to form new structures that are no longer able to store energy.”

What’s worse is that these areas of reconstructed surface apparently act as stakes that pin the rest of the material in place and prevent it from the contraction which is required to reach the fully charged state.

As a result, the lithium remains stuck in the lattice and this fatigued material can hold less charge.

With this knowledge, the researchers are now seeking effective countermeasures, such as protective coatings and functional electrolyte additives, to mitigate this degradation process and extend the lifetime of such batteries.