Since the 1990s, scientists have been exploring the possibilities of miniaturized chemical “laboratories” on a chip.

Microfluidic systems can accommodate chemical experiments on a chip through a series of small connected tubes the size of a hair.

The technology’s potential has not fully been reached because the chemical reactions are controlled by large equipment that is external to the chip.

In a recent study published in Nature, researchers from Saint Louis University shared their discovery of a way to program built-in controls in a microfluidic network.

This technology has potential for point-of-care diagnostics and health monitoring wearables, analysis kits for field research and someday even conducting chemical tests on other planets.

Since the 1990s, scientists have been exploring the possibilities of miniaturized chemical “laboratories” on a chip, which have potential as point-of-care diagnostics, analysis kits for field research and someday even conducting chemical tests on other planets.

In a normal lab, chemists use beakers to mix chemicals and study reactions.

In a miniaturized laboratory, microfluidic systems can conduct chemical experiments on a chip through a series of small connected tubes the size of a hair.

This technology currently is in use, most notably in the medical field, which creates organs-on-a chip for research. However, the technology’s potential has not fully been reached because the chemical reactions are controlled by large equipment that is often external to the chip.

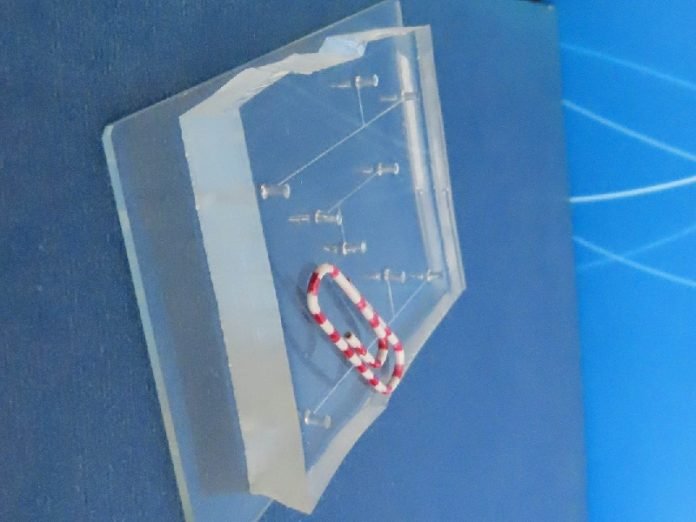

In a recent study published in Nature, researchers from Saint Louis University along with colleagues from Northwestern University and Normandie Universite shared their discovery of a way to program built-in controls in a microfluidic network.

“We took our inspiration from electronics, in which a chip’s controls are self-contained,” said Istvan Kiss, Ph.D., professor of chemistry at Saint Louis University.

“When we started the research in this field, we said ‘Why don’t we build tiny little reactors, sub-millimeter-sized. We used only a small number of reactors, so directing the flow was easy with simple, tiny tubes.

But now, to advance the technology, we need the chip to be a bit more complicated, with many reactors and tubes in between, to operate more like a circuit.”

To solve this problem, researchers combined network theory and fluid mechanics and created controls operated entirely on the chip.

Together with Yifan Liu, Ph.D., graduate research assistant at SLU and other colleagues, Kiss designed a network with a nonlinear relationship between the applied pressure and flow rate, which can be used to switch the direction of liquid flow simply by changing the input and output pressure.

Taking a cue from a counterintuitive theory about traffic patterns, the scientists found that shortcuts aren’t always the fastest way from point A to point B. A phenomenon known as Braess’s paradox has demonstrated—in traffic patterns, electronics, springs—that sometimes having more pathways to travel actually slows down traffic rather than speeds it up.

“We’ve built a network that shows that paradox,” Kiss said.

“As we studied how water molecules go around obstacles, it created a ‘valve.’ Water molecules are diverted from their paths. At low flow rates, they go towards the obstacles, while at high flow rates, they go the opposite way.”

“When we close a shortcut channel, it results in a higher, rather than lower, total flow rate. We’re interested in how such changes in flow rates and directions will eventually change the chemical reactions in the reactors.”

This technology could be used to create portable lab testing systems as well as to design new applications, such as health monitoring wearables or deployable space systems.

Written by Carrie Bebermeyer.