In a new study, researchers have developed a more cost-effective way to produce hydrogen fuel from water.

The new method uses nanoparticles composed of nickel and iron.

It is more cost effective and efficient than other more expensive materials in the production of hydrogen fuel.

The study was done by researchers from the University of Arkansas and colleagues from Brookhaven National Lab and Argonne National Lab.

In the study, the researchers found that using nanocatalysts composed of nickel and iron could increase the efficiency of water electrolysis.

During water electrolysis, engineers break water atoms apart to produce hydrogen and oxygen and then combine them with electrons to create hydrogen gas.

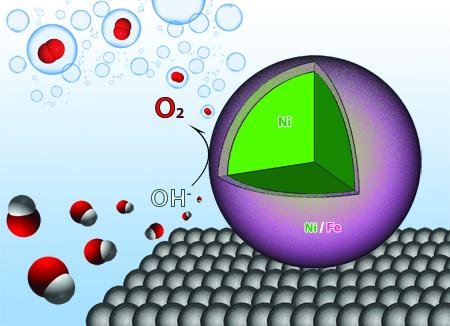

The team discovered that when nanoparticles composed of an iron and nickel shell around a nickel core are applied to the water electrolysis process, they could interact with the hydrogen and oxygen atoms to weaken the bonds.

This strongly increases the efficiency of the reaction by allowing the generation of oxygen more easily.

The team also found that nickel and iron are also cheaper than other catalysts made from scarce materials.

The researchers believe their finding helps make water electrolysis a more practical and affordable method for producing hydrogen fuel.

It is better than the current methods of water electrolysis, which are too energy-intensive to be effective.

The authors of the study are Jingyi Chen, associate professor of physical chemistry, and Lauren Greenlee, assistant professor of chemical engineering.

The study is published in the journal Nanoscale.

The project was funded by the National Science Foundation and the Department of Energy.

Copyright © 2019 Knowridge Science Report. All rights reserved.