Knitting may seem like an ancient craft, but researchers at Cornell University and Carnegie Mellon University have reimagined it for the future—by turning it into a 3D manufacturing process.

They have built a prototype knitting machine that can create solid, three-dimensional shapes by adding stitches in any direction, much like how a 3D printer builds up layers of material.

The new device can knit forward, backward, or diagonally, allowing it to construct complex forms such as curved or hollow structures.

It can even vary the stiffness in different parts of the object, opening possibilities for everything from custom fabrics to medical materials.

The researchers presented their work, titled “Using an Array of Needles to Create Solid Knitted Shapes,” at the ACM Symposium on User Interface Software and Technology in Busan, South Korea.

“We’ve shown that not only can this be done, but the way we connect the stitches gives us incredible flexibility in how we control the material,” said Professor François Guimbretière from Cornell’s Department of Information Science, who co-led the project with his son, Victor Guimbretière, an engineering student.

“The expressiveness is very similar to a 3D printer.”

Traditional knitting creates flat, 2D sheets of fabric, which must then be sewn or shaped into a final product. By contrast, this machine directly builds solid, layered structures from yarn, more like a printer that constructs objects layer by layer.

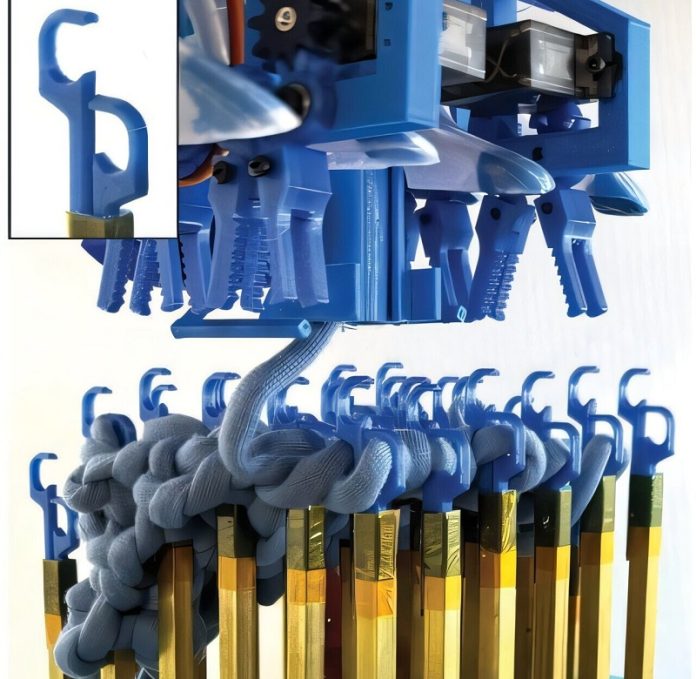

The machine’s design features a 6-by-6 grid of knitting needles, each consisting of a symmetrical double hook made with a 3D printer and attached to a brass support tube. Each hook can move independently, enabling the machine to perform both knit and purl stitches. A yarn dispenser moves freely above the needle array, laying down stitches wherever needed.

To run the system, the team wrote a custom library of code that defines each stitch type and automatically generates the knitting sequence for any chosen shape. This design allows remarkable control over where and how the yarn is laid, unlike earlier knitting machines that were limited to simple patterns or fixed motions.

So far, the prototype has successfully produced solid shapes such as a “C” and a pyramid, demonstrating its ability to handle overhangs and curved surfaces. Although the current version is slow and sometimes drops loops or misplaces stitches, Guimbretière says the system can be easily scaled up and improved by adding more needles or refining the mechanics.

Looking ahead, he believes this approach could have medical applications, such as knitting structures that mimic ligaments, tendons, or blood vessels. “Solid knitting lets us control thickness and stiffness in ways that could one day be used to create artificial tissues,” he said.

The team’s invention blends traditional textile craftsmanship with cutting-edge engineering—paving the way for a new generation of machines that knit not just fabric, but form.