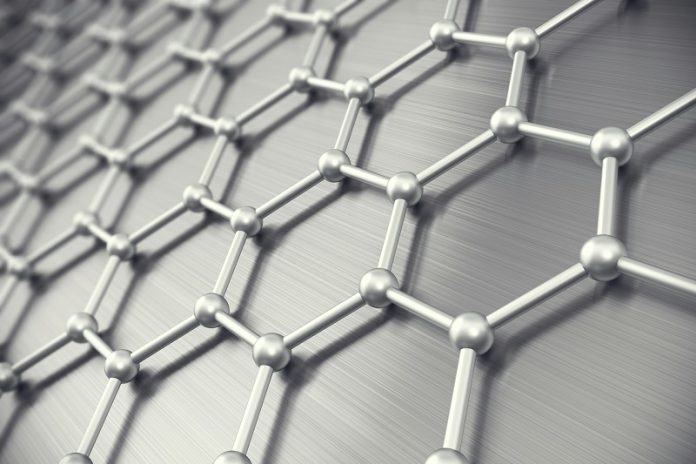

Graphene has long been called a “wonder material.” Just one atom thick, it is incredibly strong, light, and an excellent conductor of electricity.

But surprisingly, its perfection can also be a problem.

Because pure graphene is so flawless, it often interacts too weakly with other materials and misses key electronic features needed for advanced technologies.

Now, researchers from the University of Nottingham, the University of Warwick, and Diamond Light Source have developed a clever way to make graphene even more useful—by deliberately adding flaws.

Their work, published in Chemical Science, shows how tiny imperfections can actually improve graphene’s performance and open the door to new applications in electronics, batteries, and sensors.

Instead of treating defects as mistakes, the team used a molecule called Azupyrene to grow graphene-like films with built-in irregularities.

Normally, graphene’s structure is a perfect honeycomb pattern of six-carbon rings.

By contrast, Azupyrene naturally contains five- and seven-carbon rings, which mimic the kind of defects the scientists wanted to introduce. Using this molecule in a single-step growth process, they were able to “bake in” controlled defects right from the start.

These carefully designed flaws gave graphene new properties.

The defective graphene proved more “sticky,” meaning it bonded more strongly with other materials—a useful trait for catalysts and chemical sensors.

The defects also changed the way electrons and magnetic fields behaved inside the material, which could make it more suitable for use in the semiconductor industry.

Another key step was showing that the defective graphene could be transferred to different surfaces while keeping its useful flaws intact. This was demonstrated by researchers at the Graphene Institute in Manchester, proving the material could be applied to real-world devices.

The team combined advanced tools from across the UK, Germany, and Sweden to confirm their findings.

Using high-resolution microscopes, powerful spectroscopic methods, and supercomputer simulations on the UK’s ARCHER2, they were able to see the atomic structure of the defects and measure how they influenced the material’s properties.

Professor Reinhard Maurer of the University of Warwick explained that by carefully choosing the starting molecule and growth conditions, they could control how many imperfections appeared.

Dr. Tien-Lin Lee from Diamond Light Source added that the international teamwork was essential, as no single method or lab could have achieved the same insights alone.

This new approach flips the script on how we think about materials. Instead of chasing absolute perfection, scientists are showing that sometimes flaws are exactly what’s needed to unlock new possibilities. For graphene, it could mean a future where “imperfect” is actually better.