Rotating parts like boat propellers, turbines, and hydraulic pumps often face a serious problem: vibration caused by swirling currents of air or water.

These vibrations can wear down machinery, reduce efficiency, and even lead to dangerous failures.

Now, a Ph.D. student at the Swiss Federal Institute of Technology Lausanne (EPFL) has developed a clever device that drastically cuts down on this type of vibration—and it can be made with a simple 3D printer.

The discovery was made by Thomas Berger, a young researcher in EPFL’s School of Engineering, who describes his invention as something of a lucky breakthrough.

Early in his doctoral studies, Berger built on work he had started as a master’s student, experimenting with new shapes using 3D printing.

His persistence led to a promising device that has already been patented and is now drawing the attention of potential investors.

Berger carried out his work in the lab of Professor Mohamed Farhat, which specializes in studying how fluids behave in complex situations.

One of the toughest challenges in the field is what engineers call “flow-induced vibration,” especially in turbines. These powerful machines, used in hydropower plants and other energy systems, are constantly exposed to water rushing past their blades.

That flow can create repeating patterns of swirling currents—known as vortices—that shake the machinery and cause damage.

The phenomenon isn’t new. Vortices form whenever a fluid flows past an obstacle, whether it’s a wing, a skyscraper, or a bridge.

The alternating swirls exert an oscillating pressure that produces vibration. Some vortices can be extremely destructive: the infamous collapse of the Tacoma Narrows Bridge in 1940 was caused by this very effect.

Named after the engineer Theodore von Kármán, who first described them in 1911, these vortices remain a key problem for designers of turbines, aircraft, and ships.

Berger found inspiration in an unexpected place: the Eiffel Tower. Built in 1887, long before von Kármán’s discovery, the tower’s porous iron structure happened to prevent strong vortices from forming, essentially saving it from destructive vibrations. That idea of porosity sparked Berger’s search for a structure that could interrupt vortex formation on turbine blades.

Instead of relying on existing theories—which still cannot accurately predict how severe vibrations will be—Berger turned to hands-on testing. Using 3D printing, he created a series of different shapes and materials, tested them, and refined his designs. Eventually, he hit upon one shape that stood out: the gyroid.

The gyroid is a mathematically derived 3D form made up of continuous curved surfaces. It is lightweight yet strong, porous yet sturdy, and surprisingly well-suited to breaking up the flows that cause vortices.

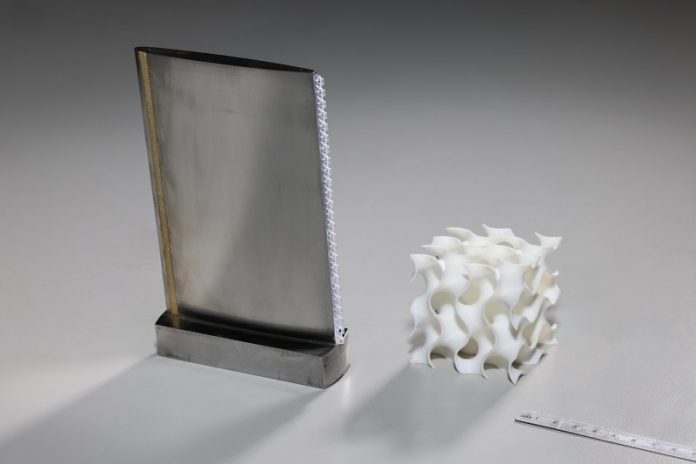

Berger glued a small 3D-printed gyroid, made from resin, onto the trailing edge of a steel blade and ran experiments in a flow tunnel. The results were striking—no vortices formed, and the blade stopped vibrating altogether.

“The gyroid stops the vortex right at the source,” said Professor Farhat. “And the best part is that it doesn’t affect the blade’s performance.”

The exact reason why the gyroid shape works so well is still a mystery. Berger admits his research took an unusual path: he discovered the solution first, and only now is he working out the science behind it.

For now, though, the device’s practical benefits are clear, and companies are already showing interest in bringing it to real-world machines.

The next step will be testing the technology under more demanding conditions, such as inside full-sized turbines.

If successful, this innovation could make turbines, pumps, and propellers more reliable, efficient, and durable—showing once again how a simple idea, combined with modern tools like 3D printing, can solve problems that have challenged engineers for over a century.