From foldable phones and smartwatches to medical sensors and portable solar panels, flexible electronics are becoming part of everyday life.

These devices bend, fold, and roll in ways that traditional electronics cannot, opening the door to new designs and applications.

But their durability remains a major concern. Can these devices survive thousands of bends without breaking down?

A new study from Brown University suggests the answer is more complicated than scientists once thought.

Engineers discovered that cracks in the thin, brittle electrode layer on top of flexible devices can spread into the softer polymer substrate beneath it. This overturns the long-held belief that the polymer layer—the foundation of flexible electronics—was resistant to cracking.

“The substrate in flexible electronics is like the foundation of a house,” explained Nitin Padture, a professor of engineering at Brown and senior author of the study, published in npj Flexible Electronics.

“If it cracks, the structural integrity of the entire device is compromised.”

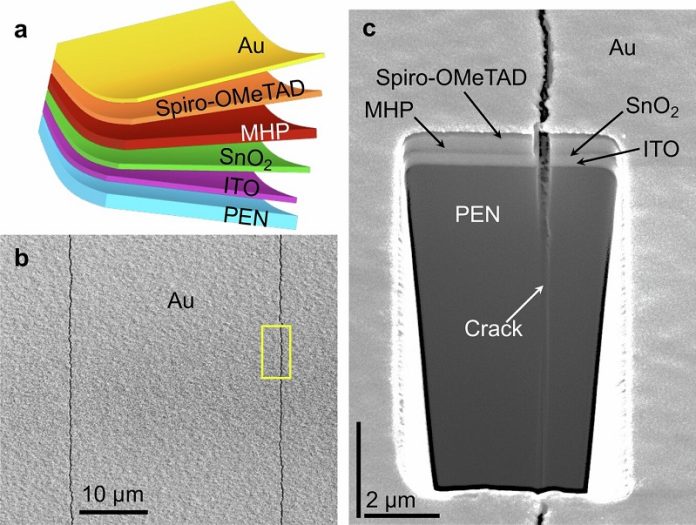

Flexible devices typically combine two layers: a ceramic electrode layer that conducts electricity, and a polymer substrate layer that provides toughness and flexibility.

Ceramic materials are chosen because they are transparent and conduct electricity well, which is essential for displays, solar cells, and sensors. But ceramics are also brittle and prone to cracking, which is why the polymer foundation is so important.

Anush Ranka, who led the research as a Ph.D. student in materials science at Brown, wanted to understand how repeated bending weakens these devices.

He built experimental samples with different combinations of ceramic electrodes and polymer substrates, then bent them thousands of times. Using powerful microscopes, he discovered that cracks in the ceramic didn’t just stay on the surface—they often pushed deeper into the polymer layer.

Once cracks formed in the polymer, they became permanent structural flaws. With continued bending, these cracks widened, shifted, or collected debris. This prevented the ceramic layers above from reconnecting, leading to greater electrical resistance and degraded performance.

Working with colleagues specializing in mechanics, Ranka found the cause: a mismatch in the mechanical properties of the ceramic and polymer layers. To solve this, the team added a thin third layer between the two materials to ease the mismatch.

Using a design map they created, they identified hundreds of potential polymers that could work as a buffer. In experiments, they demonstrated that this approach successfully reduced cracking.

The findings not only point to a practical fix but also reveal a problem no one had realized existed. “We’re essentially solving a problem people didn’t know they had,” said Padture. “This discovery could significantly extend the life of flexible electronics.”

As demand for foldable and wearable devices grows, solutions like this may be critical for making them more durable, reliable, and sustainable.