A new generation of modular robots is proving they can handle tough tasks outside the lab.

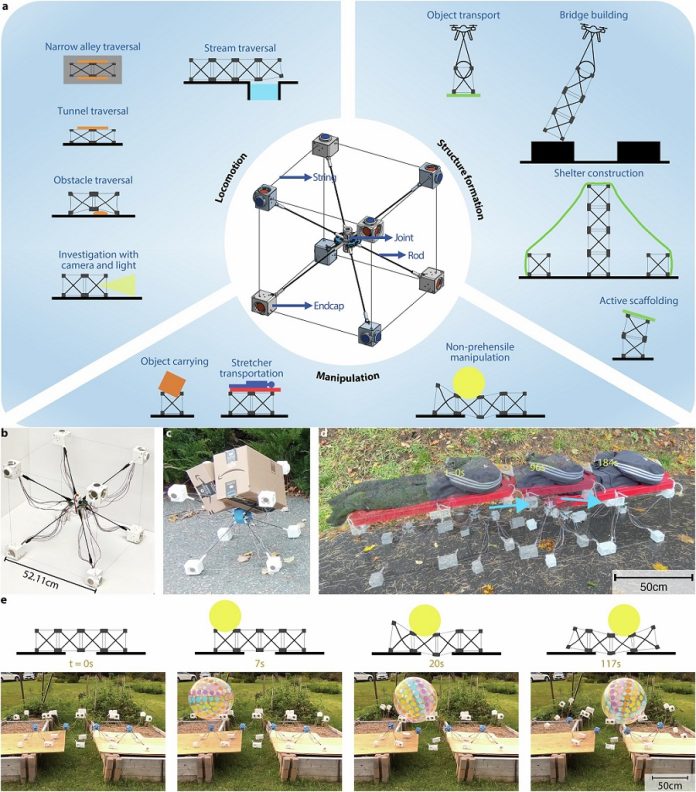

Developed by researchers at Dartmouth College along with collaborators from Rutgers University and Yale University, these robots are designed to link together and form useful structures—from makeshift bridges to simple shelters.

The robots are built from cube-shaped blocks that combine hard, rigid rods with soft, stretchable strings.

By tightening or loosening the strings, the blocks can change shape, which allows them to move, connect with other blocks, and assemble into larger structures. “Modular robots are versatile.

By combining the blocks differently, we can use them in many different ways,” explained Dartmouth graduate student Luyang Zhao, who led the work with fellow student Yitao Jiang at the Dartmouth Reality and Robotics Lab.

To test their design, Zhao and Jiang took the robots outdoors around campus. The cube-bots crawled under fallen logs, squeezed through narrow gaps, and even linked together to form makeshift scaffolding for tents.

In one test, the robots worked with a drone to locate and recover a broken block.

Drawing inspiration from ants that form living bridges, the researchers also showed that a line of connected robots could span a small brook and even carry light objects across the gap.

The robots are not yet strong enough to carry people, but the team did build a stretcher by placing a board across a short chain of blocks. This prototype was able to carry a human dummy, hinting at future applications.

Zhao believes these robots could one day play an important role in disaster relief. “The robots are lightweight and deployable but also quite robust. They can be air-dropped anywhere and quickly assembled into a bridge or support a temporary shelter,” she said.

Each robotic block contains eight rigid rods extending from a 3D-printed central hub. Inside this hub is a battery that powers the robot and a Wi-Fi module that allows it to move freely while staying connected.

On the ends of the rods are caps attached by strings. Small motors control the length of the strings, enabling the block to shift its shape.

The end-caps also have 3D-printed latches that allow one block to snap securely onto another. On a single charge, the robots can “walk” and operate for more than three hours.

One of the most fascinating features is how much movement the system produces from relatively small deformations.

“The units built out of the pieces combine the structure and the motion together in a very nice way,” explained Devin Balkcom, a professor of computer science at Dartmouth and the project’s principal investigator.

The researchers are especially excited about combining drones with these robots. While linking modules together on the ground is straightforward, building tall or complex structures is difficult. By using drones to lift and place the modules, the process becomes more like 3D printing, with the ability to quickly configure and reconfigure larger structures in the air.

This is the first time modular robots have demonstrated such a wide range of functions outside of a controlled lab setting.

Zhao, now an assistant professor at Clemson University, sees plenty of opportunities for improvement. The team hopes to make the robots stronger so they can carry more weight and smarter by adding sensors that will allow them to adapt to their surroundings on their own.

For now, the outdoor experiments show just how flexible and promising these modular robots are. From bridging gaps to building shelters, their ability to reshape themselves and work together could make them valuable tools in real-world emergencies.