Researchers in South Korea have created a new type of light-sensitive device that could transform how wearable electronics are made.

The breakthrough, led by Dr. Jung-Dae Kwon and his team at the Korea Institute of Materials Science (KIMS), allows for the production of flexible optoelectronic devices using a much cooler manufacturing process—just 90°C, compared to the usual 250°C or higher.

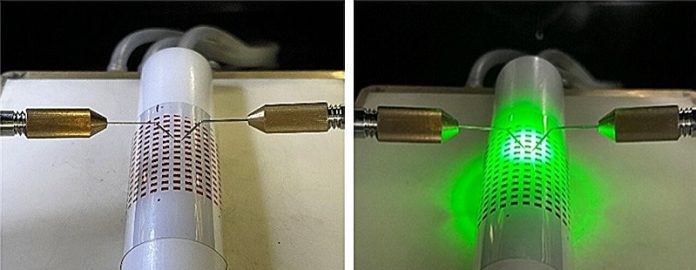

Optoelectronic devices are tools that can detect light and convert it into electrical signals.

They are widely used in things like image sensors, health monitors, and other wearable technologies.

Until now, building these devices required high temperatures that could damage the flexible materials often used in wearables. That’s been a major roadblock for engineers trying to create durable and comfortable electronics that can bend and move with the body.

Dr. Kwon’s team overcame this challenge by carefully adjusting the mix of gases used during a process called plasma-enhanced chemical vapor deposition (PECVD).

In particular, they focused on the ratio of hydrogen to silane gas, a key factor in forming the thin films that make up these devices. This fine-tuned approach allowed them to create high-quality films at a much lower temperature.

To further improve the material’s performance, the team used hydrogen to “passivate” the film—essentially filling in defects that would otherwise interfere with how well the device works.

The result was an optoelectronic device that works nearly as well as those made with traditional high-heat methods. In fact, it achieved about 96% of the light sensitivity of high-temperature versions.

Another clever part of their process involved using a material called photoresist. This acts as a temporary layer that makes it easier to form precise active areas on the device. After its job is done, the photoresist can be easily removed, making the overall process simpler and more efficient.

Durability was also a key test. The team bent their device more than 2,700 times at a tight radius of 5 millimeters. Even after all that stress, the device still worked perfectly, showing excellent mechanical strength and flexibility.

Dr. Kwon says this method could lead to cheaper and more efficient production of flexible electronics, opening up new possibilities in wearable tech, health monitoring, and imaging devices.

With its low energy demands and strong performance, this low-heat approach may set a new standard for building the next generation of smart, flexible electronics.