Deep beneath the border of Switzerland and France lies the world’s largest and most powerful scientific instrument—the Large Hadron Collider (LHC).

This 17-mile-long tunnel accelerates particles to near the speed of light and smashes them together, helping scientists unlock the secrets of the universe.

But these powerful collisions don’t just create valuable data—they also release intense radiation, enough to damage or destroy almost any standard electronic equipment.

That’s a serious challenge for physicists working at CERN, the European lab that runs the LHC.

The collider generates huge amounts of data from every collision, but no ordinary chip can survive the radiation long enough to record it.

Unfortunately, radiation-resistant electronics are so specialized that commercial chip makers don’t have much incentive to build them.

So engineers and scientists teamed up to solve the problem themselves.

Columbia University professor Peter Kinget, an expert in electrical engineering, led a team that designed custom silicon chips tough enough to work inside the LHC. Their newest chip designs were detailed in a paper published July 1 in the IEEE Open Journal of the Solid-State Circuits Society.

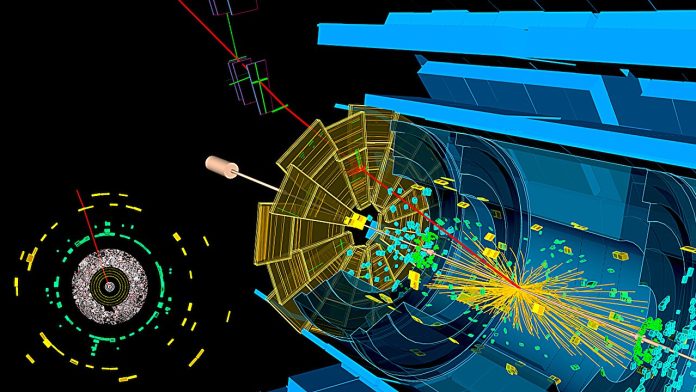

These chips are a crucial part of one of the LHC’s most important instruments—the ATLAS detector, which helped discover the Higgs boson in 2012.

The chips, called analog-to-digital converters (ADCs), perform a vital job: they take the faint electrical signals produced when particles collide and turn them into precise digital data that scientists can analyze.

The ATLAS detector uses ultra-cold liquid argon to catch traces of every particle that flies through it. These traces are tiny pulses of electricity, and Columbia’s custom chips convert them into data that captures the fine details of each collision.

The project started when the team realized that regular, store-bought components simply couldn’t handle the LHC’s radiation.

“We tested standard, commercial components, and they just died,” said Ray Xu, a Ph.D. student at Columbia who’s been part of the project since his undergraduate days at the University of Texas. “We realized that if we wanted something that worked, we’d have to design it ourselves.”

Rather than inventing entirely new manufacturing techniques, the team used commercial chip-making processes that had already been tested for radiation resistance by CERN. Then, they applied advanced engineering methods to carefully design and arrange the circuits to limit radiation damage. They also included error-correction systems that fix problems in real time, ensuring the chips can work reliably for more than ten years inside the LHC.

Two key chips emerged from this work. The first, called the “trigger ADC,” is already installed at CERN. It acts as a smart filter, sorting through about a billion particle collisions every second and selecting only the most interesting ones for scientists to study further.

The second chip, the “data acquisition ADC,” has just finished testing and is about to be installed. It will provide extremely accurate digital measurements of selected events, helping researchers dive deeper into the mysteries of particles like the Higgs boson.

These chips are the result of a close partnership between engineers and physicists at Columbia University and the University of Texas. Columbia’s Nevis Laboratories is helping lead this international effort, which is pushing the boundaries of what we know about the universe.

As Xu put it, “The chance to contribute to such fundamental science as an engineer is what makes this project so special.”