Researchers at South Korea’s Pohang University of Science and Technology (POSTECH) have created a groundbreaking material that can stick to tiny objects like micro-LED chips and let go of them just as easily—without using glue.

This discovery could solve one of the biggest challenges in making next-generation display screens.

Micro-LEDs are small but powerful lights that are used to build advanced screens.

They are brighter, last longer, and can be used in flexible or even see-through displays.

However, putting these tiny LED chips—each thinner than a strand of hair—onto the right surface has been very difficult. Traditional methods use sticky liquids or special films, which often leave a mess behind or don’t line up the chips properly.

The POSTECH team, along with researchers from other universities in Korea and the United States, developed a new kind of dry adhesive using shape memory polymers (SMPs).

These materials are smart—they can change their shape or texture when heated. On the surface of the SMP, the team added millions of tiny tips, or “nanotips,” that play a key role in controlling stickiness.

At room temperature, the surface is rough and doesn’t stick much at all. But when it’s heated and pressed onto another surface, the material softens and flattens out, allowing it to grip very strongly—like ironing out wrinkles.

Later, when the surface is heated again, it returns to its original rough shape, letting go of whatever it was holding. This switch between “stick” and “release” can be controlled very precisely.

This smart adhesive can hold objects with over 15 times the pressure of the Earth’s atmosphere, and then release them with almost no force. That’s a difference of more than 1,000 times between when it’s gripping and when it’s letting go—far better than older techniques.

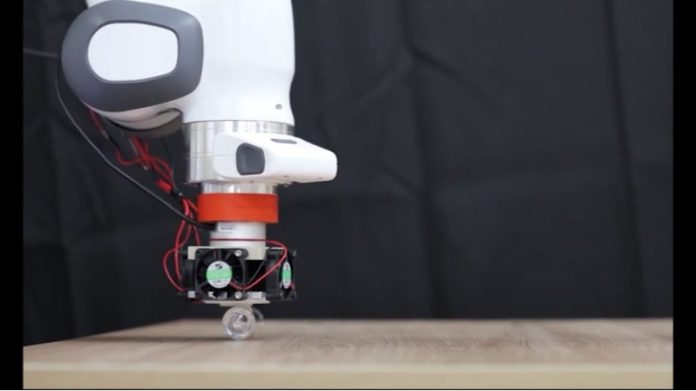

The team showed that their material could be used with a robotic arm to move tiny micro-LED chips and even unusual materials like paper or cloth. This could lead to faster, cleaner, and more accurate manufacturing in electronics, displays, and even everyday products.

Professor Seok Kim, who led the study, said this new material could transform how things are made in factories. “It lets us handle delicate parts without any mess,” he explained, “and could be a big step forward for future technologies.”