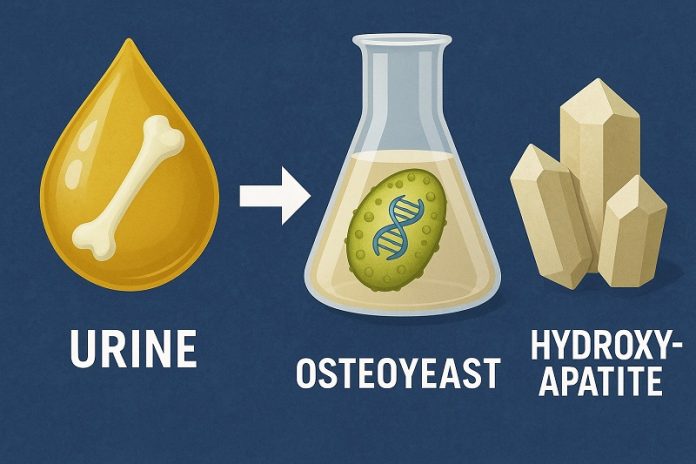

What if human urine could be turned into something incredibly useful—like a material for dental or bone implants?

A team of researchers has done exactly that by creating a new biological process that transforms urine into hydroxyapatite, a valuable mineral widely used in medicine, archaeology, and even construction.

Hydroxyapatite, or HAp, is a calcium phosphate mineral found naturally in human bones and teeth.

It’s biocompatible, durable, and projected to reach a market value of over $3.5 billion by 2030.

Now, scientists from the University of California, Irvine and several international institutions have found a way to make HAp using urine and specially engineered yeast.

Published in Nature Communications, the study presents a yeast-based platform that converts urine—often a pollutant in wastewater—into high-value material.

This method not only helps reduce environmental harm but also creates a renewable product that could replace plastics and other synthetic building materials in the future.

The key to this breakthrough is a synthetic yeast nicknamed “osteoyeast.” Inspired by mammalian bone cells called osteoblasts—which naturally form hydroxyapatite in the body—the researchers designed this yeast to mimic the same process but on a larger, industrial scale.

In this engineered system, enzymes in the osteoyeast break down urea in urine, which increases the surrounding pH.

This change causes tiny pockets inside the yeast cells to collect calcium and phosphate, which are then secreted and crystallized into hydroxyapatite.

The process is surprisingly quick, taking less than a day to produce HAp, and can yield about one gram of the mineral per liter of urine. Even more promising, it doesn’t require expensive equipment or high temperatures.

It works in fermentation vats similar to those used in beer brewing, making it accessible for large-scale production—even in low-resource settings.

“This approach tackles two problems at once,” said coauthor David Kisailus, professor of materials science at UC Irvine. “It cleans up wastewater while creating something incredibly useful.”

Because yeast is cheap and easy to grow, this process could be scaled up globally. It could also reduce reliance on mining or synthetic production of materials that are harmful to the environment.

Kisailus, who studies crystal growth and bio-inspired materials, worked closely with coauthor Yasuo Yoshikuni from Lawrence Berkeley National Laboratory. The team is now expanding the method to create other useful substances for energy and building applications, even exploring 3D printing technologies to shape these new materials into practical structures.

This work was funded by the U.S. Department of Energy, DARPA, and the Air Force Office of Scientific Research, showing the strong interest in sustainable, science-driven innovation.

Source: UC Irvine.