A team of engineers at the University at Buffalo is turning an everyday farming byproduct—wheat straw—into a powerful, eco-friendly material to insulate buildings.

Instead of relying on traditional insulation materials that are energy-intensive to produce, this new approach uses agricultural waste that’s usually burned after harvest, contributing to air pollution and carbon emissions.

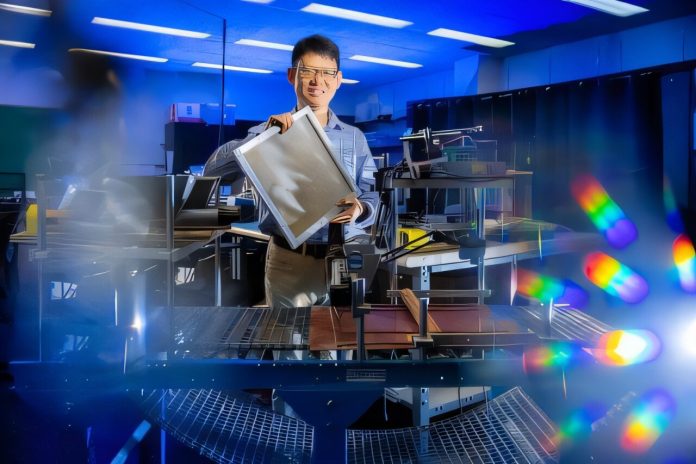

Wheat straw is the stalk left over after wheat is harvested. Chi Zhou, an engineering professor at UB, saw potential in this material for use in thermal insulation.

Unlike materials made from fossil fuels, wheat straw is renewable, biodegradable, and can be grown and harvested repeatedly.

Its natural structure—full of fibrous and porous properties—makes it great at slowing down heat transfer, meaning it helps keep homes warm in winter and cool in summer.

Zhou and his team began researching how to turn wheat straw into a usable building material in 2022. They developed a process to grind the straw into fibers and mix it with an organic binder.

Through hydrogen bonding, this mix becomes strong and durable.

They then transformed it into a thick ink that can be used in a 3D printer to create insulation panels and shapes.

What’s unique about this work is that it’s the first time anyone has 3D printed wheat straw fibers specifically for thermal insulation. The research was recently published in the Journal of Manufacturing Science and Engineering and will be presented at a major engineering conference in June 2025.

Currently, the insulation market is dominated by materials like fiberglass and rock wool. While effective, these materials require fossil fuels to produce, which contributes to greenhouse gas emissions. In contrast, wheat straw is not only more sustainable, but also offers other benefits.

It has good insulation performance, is flame resistant, and can be made into various shapes and products—from insulation panels to furniture and kitchenware.

To make this process more efficient, Zhou’s team improved the 3D printing setup. Traditional printers are slow and print in small lines. The team developed a new nozzle that spreads the material more widely and evenly.

They also used multiple nozzles at once and created a system to make sure the flow stays consistent. This allowed them to create larger panels more quickly in their lab at UB.

The next step is finding an industrial partner to help bring this technology to market.

If successful, wheat straw insulation could reduce both agricultural waste and greenhouse gas emissions, while supporting local farms and offering a cost-effective, sustainable solution for keeping buildings comfortable year-round.

Source: University at Buffalo.