A research team at POSTECH has developed a new method for making perovskite nanocrystals (PNCs) in a more efficient and uniform way.

This breakthrough could help speed up the commercialization of optoelectronic devices like LEDs and solar cells that use nanocrystals.

The study was led by Professors Young-Ki Kim and Yong-Young Noh from POSTECH’s Department of Chemical Engineering, along with Ph.D. candidate Jun-Hyung Im, Dr. Myeonggeun Han (Samsung Electronics), and Dr. Jisoo Hong (Princeton University).

Their findings were recently published in ACS Nano.

Why are perovskite nanocrystals important?

PNCs are a promising material for future solar cells and high-quality displays because their ability to absorb and emit light can be precisely controlled based on their size and shape.

However, traditional methods of making PNCs, such as hot-injection and ligand-assisted reprecipitation (LARP), have challenges.

These methods often require high temperatures and complicated steps, making it difficult to produce nanocrystals with uniform sizes and shapes. Additional processing steps are needed, which lowers efficiency and limits large-scale production.

To solve this problem, the POSTECH team developed a method that uses liquid crystals (LCs) as an antisolvent in the LARP process.

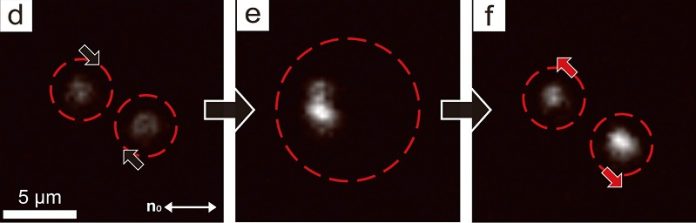

LCs are materials that have properties of both liquids and solids, allowing their molecules to align in a specific direction while remaining fluid. This unique feature makes them useful in controlling the growth of PNCs.

By replacing the antisolvent in the LARP method with LC, researchers found they could precisely control the size and shape of PNCs without needing extra purification steps.

The elastic properties of LCs restricted the growth of PNCs, ensuring they remained uniform in size. This method enables mass production of high-quality PNCs at room temperature, making it more practical for industrial applications.

Another key discovery was that the interaction between LC molecules and surface ligands of PNCs helps reduce defects. Because LC molecules have a long, rod-like shape, they help ligands arrange themselves more densely around the nanocrystals.

This results in fewer surface defects and improved luminescence properties, making the nanocrystals more efficient for use in electronic devices.

Professor Kim explained, “Our synthesis method works well with existing techniques like ligand exchange and microfluidic synthesis. It will enhance the performance of various optoelectronic devices, including LEDs, solar cells, lasers, and photodetectors.”

This new approach allows for the large-scale production of high-quality nanocrystals without complicated processes.

The researchers hope their work will help speed up the use of nanocrystal-based optoelectronic devices in everyday applications.