Engineers have developed a new, cost-effective way to create specially patterned aluminum surfaces that could revolutionize cooling systems, self-cleaning technologies, and anti-icing solutions.

This breakthrough comes from an international team at Rice University and the University of Edinburgh, who used simple tools and materials to create surfaces with advanced properties.

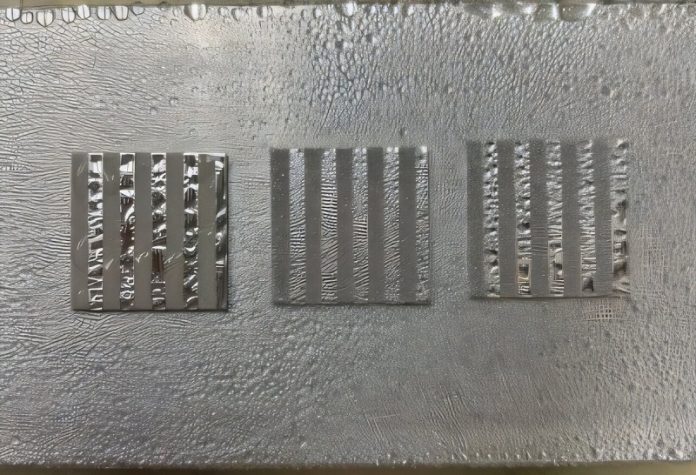

The research, published in the journal Langmuir, demonstrates how a technique involving vinyl masking and chemical treatments can produce aluminum surfaces with unique textures and properties.

These textures help manage liquids more efficiently, improving heat transfer and preventing issues like ice buildup or dirt accumulation.

Importantly, this method is scalable, meaning it can be applied to larger surfaces and used in industrial settings.

The team’s process starts with applying vinyl masks, cut with precision, to polished aluminum.

The masked aluminum then undergoes a two-step etching process that creates tiny micro- and nano-sized textures in specific areas.

By controlling this patterning, the researchers can make some parts of the surface repel water (superhydrophobic) while others attract it (hydrophilic).

The ability to control how liquids interact with the surface has significant advantages. For example, droplets of water can slide off superhydrophobic areas more easily, helping to improve condensation processes.

At the same time, hydrophilic regions can enhance heat transfer by keeping a thin layer of water in place.

To evaluate their design, the researchers performed experiments to see how the surfaces handled condensation. They found that droplets shed more efficiently from the patterned aluminum compared to traditional, uniform surfaces. This improved droplet movement reduces the thermal resistance caused by large water droplets during condensation, making it ideal for cooling applications.

Additionally, the researchers used infrared imaging to study the thermal properties of the surfaces. They found that the patterns created on the aluminum not only improved liquid handling but also enhanced heat dissipation. For instance, textured areas emitted more infrared radiation, helping to release heat faster.

To demonstrate the precision of their patterning method, the team even created aluminum surfaces with designs of iconic symbols, such as Edinburgh Castle and the Rice University owl. Infrared imaging showed these patterns in bright contrast, highlighting the technique’s potential for creating customized thermal solutions.

This technology has wide-ranging applications. In electronics cooling, the improved condensation process can help prevent overheating in devices like data center servers. In high-temperature environments, such as car engines or aerospace systems, the enhanced heat dissipation could lead to better performance and reliability.

The anti-icing properties are especially useful in cold conditions. Superhydrophobic patterns help water slide off surfaces before it can freeze, making this method practical for airplane wings, wind turbines, and power lines.

What sets this technique apart is its simplicity and affordability. Traditional methods like photolithography are expensive and limited to small areas. By contrast, this new method uses accessible materials and tools, making it suitable for large-scale manufacturing.

“This is a game-changer for industries that rely on heat transfer and liquid management,” said Daniel J. Preston, a mechanical engineering professor at Rice University. “Our approach not only improves functionality but also makes it possible to apply these advancements on an industrial scale.”

This research opens the door to a range of practical solutions for everyday technologies, offering better cooling, cleaner surfaces, and improved safety in icy conditions—all with a cost-effective and scalable method.

Source: Rice University.