Space exploration is one of humanity’s most ambitious ventures, but it comes with enormous challenges. Rockets and spacecraft must carry everything needed for the mission, from tools to spare parts, all while minimizing weight and cost.

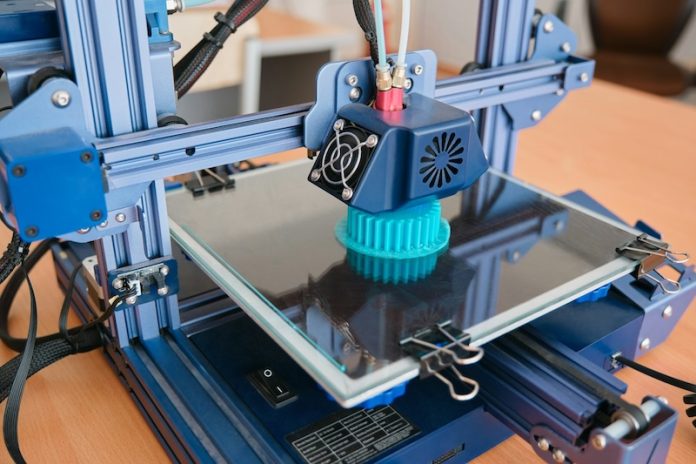

Enter 3D printing, a technology that is changing the way we approach space exploration. Also known as additive manufacturing, 3D printing allows us to create objects layer by layer from materials like plastic, metal, and even lunar dust.

This groundbreaking method is helping scientists and engineers solve problems in space in ways we never thought possible.

One of the most important benefits of 3D printing is its ability to make parts on demand. Imagine a spaceship millions of miles from Earth where something breaks. Sending a replacement part from Earth would be impractical and could take months or years.

With a 3D printer on board, astronauts can simply print the part they need using a digital blueprint. This idea has already been tested. In 2014, NASA installed a 3D printer on the International Space Station (ISS).

Astronauts used it to print tools and parts, proving that the technology works in microgravity. For instance, they printed a wrench from a design sent directly from Earth, eliminating the need to carry spares for every possible scenario.

Another exciting use of 3D printing is building rockets and spacecraft. Traditional manufacturing methods often involve cutting or welding large pieces of material, which can be expensive and time-consuming.

With 3D printing, complex rocket components can be made as a single piece, reducing waste and saving money. For example, SpaceX, one of the leading private space companies, uses 3D printing to create rocket engines.

This approach has sped up production while maintaining high performance and reliability. Similarly, NASA’s Perseverance rover, which landed on Mars in 2021, carried 11 3D-printed parts, including key components for its instruments.

Looking even further into the future, 3D printing could be the key to building habitats on the Moon or Mars. Transporting building materials from Earth to another planet would be extremely costly and inefficient.

Instead, scientists are developing ways to use local resources, such as Martian soil or lunar dust, to “print” structures. A project by NASA and other organizations has already demonstrated that simulated lunar regolith (a material similar to Moon dust) can be used as a raw material for 3D printing.

This technology could one day enable us to construct shelters, landing pads, and roads on other planets without bringing supplies from Earth.

Even food for astronauts might be 3D-printed in the future. Long missions to Mars or beyond would require sustainable food systems, and 3D printing could provide a solution.

Scientists are experimenting with printers that can create meals from nutrient-rich pastes, offering astronauts both variety and nutrition while reducing the need to carry large amounts of pre-packaged food.

There are still challenges to overcome. Printing in microgravity, for example, requires special adjustments to ensure materials stay in place during the process.

Additionally, 3D printers need raw materials, which can be bulky to transport or limited in supply. However, researchers are exploring ways to recycle waste materials and even use resources found in space to address these issues.

The potential of 3D printing in space is enormous. It can make missions safer, more efficient, and more sustainable, opening new possibilities for exploration and colonization.

By reducing reliance on Earth-based resources, we can take bigger steps toward becoming an interplanetary species. As 3D printing technology continues to improve, it is likely to become a cornerstone of humanity’s efforts to explore and settle the final frontier.

Copyright © 2025 Knowridge Science Report. All rights reserved.