The rapid growth of electronic devices has led to a massive increase in electronic waste (e-waste).

In 2022, around 62 million tons of e-waste were generated—an 82% rise since 2010—and experts predict this could climb to 82 million tons by 2030.

E-waste contains valuable materials like metals, semiconductors, and rare elements, which can be reused.

However, less than a quarter (22.3%) of e-waste was recycled in 2022. This means precious materials worth almost $62 billion were thrown away in landfills, contributing to pollution and wasting resources.

While recycling efforts have improved, traditional methods are labor-intensive and often rely on hazardous chemicals. Many countries also send e-waste to developing nations, where informal recycling processes harm both workers and the environment.

Now, scientists have developed a cleaner, more efficient way to recycle e-waste using microwave technology.

Researchers from Sophia University in Japan and Università di Pavia in Italy have created a method called microwave-induced pyrolysis to recycle electrical cables. This breakthrough was recently published in RSC Advances.

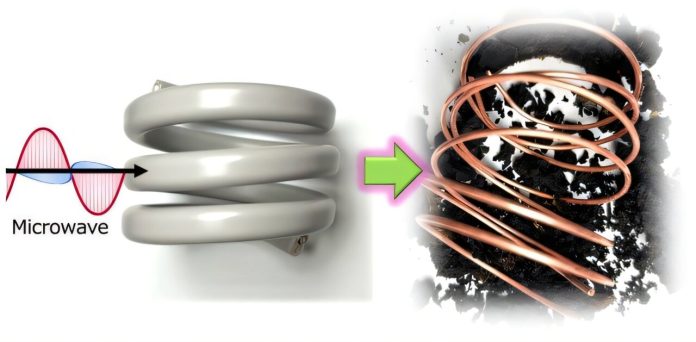

This innovative method uses microwaves to heat and break down the plastic insulation on electric cables without damaging the copper wire inside. The process also avoids creating toxic byproducts like tar or harmful gases.

The team focused on VVF cables, which are commonly used in buildings and contain two copper wires coated in PVC insulation. Instead of separating the plastic and metal beforehand, the cables were placed directly into a glass reactor and exposed to microwaves at varying power levels (100–300 W). To prevent combustion, nitrogen gas was used to create a safe, oxygen-free environment.

The microwaves heat the copper wires, causing the surrounding PVC to carbonize and expose the copper. Longer cables, like a standard 54 cm wire, were completely processed in just 12 minutes under 300 W power, leaving the copper intact and ready for reuse.

Plastics like PVC don’t absorb microwaves easily, but the copper wires in the cables act as antennas, trapping the radiation and heating up. This heating causes the PVC to break down, releasing chlorine and turning the plastic into carbon. Remarkably, this process also prevents the formation of dangerous byproducts like dioxins and polycyclic aromatic hydrocarbons (PAHs).

The length of the cable affects how well it absorbs microwaves. Wires close to the microwave wavelength of 12.24 cm (or fractions of it) worked best. For example, 9 cm and 18 cm cables began pyrolyzing at lower power levels, while shorter wires required more energy to start the process.

Currently, only 35% of PVC insulation is recycled, but microwave-induced pyrolysis offers a faster, less labor-intensive solution. It not only recovers valuable copper but also recycles byproducts. Chlorine can be reused as hydrochloric acid, and the carbon left behind can become carbon black, used in products like tires and printer ink.

This groundbreaking method could revolutionize how we recycle e-waste, reducing landfill waste and pollution while recovering valuable resources. It’s a win-win for the environment and the economy.

Source: KSR.