Diesel-powered vehicles are a major contributor to carbon emissions, which are difficult to reduce.

In the U.S., diesel fuel use accounted for about 25% of transportation-related carbon dioxide emissions in 2022, according to the U.S. Energy Information Administration.

It also made up 10% of the country’s total energy-related carbon dioxide emissions. A team of scientists has now developed a cleaner and more efficient alternative: electro-biodiesel.

Led by Joshua Yuan of Washington University in St. Louis and Susie Dai of the University of Missouri, with collaborators from Texas A&M University, the team created electro-biodiesel using carbon dioxide and a process called electrocatalysis.

Their breakthrough is 45 times more efficient and uses 45 times less land compared to biodiesel made from soybeans. This innovation could significantly lower emissions and transform renewable fuel production.

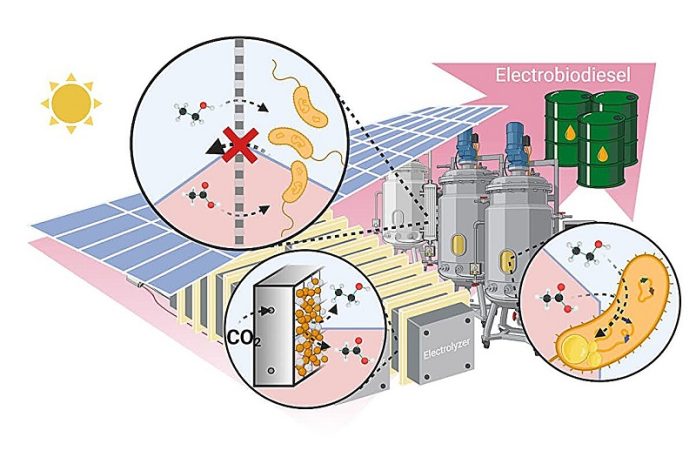

The process combines electricity, carbon dioxide, and microbes. First, carbon dioxide is converted into biocompatible chemicals like acetate and ethanol using electrocatalysis, a chemical reaction powered by electricity.

The team designed a special catalyst made of zinc and copper to make this step highly efficient.

Next, these chemicals are fed to microbes, specifically an engineered strain of bacteria called Rhodococcus jostii, which transforms them into lipids, the main ingredient in biodiesel.

Their method achieved a solar-to-molecule efficiency of 4.5%, meaning it converts 4.5% of solar energy into biodiesel feedstock. This is a huge leap compared to natural photosynthesis in plants, which is less than 1% efficient when converting sunlight into biomass.

The team’s electro-biodiesel process not only uses less land and energy but also has the potential for negative carbon emissions. For every gram of electro-biodiesel produced, the process removes 1.57 grams of carbon dioxide from the atmosphere, thanks to by-products like ethylene and biomass.

This is a stark contrast to conventional diesel and traditional biodiesel, which produce significant amounts of carbon dioxide.

“This is a big step toward making fuels, chemicals, and materials in a more sustainable way,” said Yuan, who also directs a center focused on decarbonization research. “It could help industries that rely on fossil fuels, like trucking and aviation, move toward renewable energy sources.”

The researchers see this technology as a way to solve the biodiesel feedstock shortage and reduce dependence on fossil fuels. They hope it will lead to cleaner manufacturing practices across many sectors, helping to tackle climate change and reduce humanity’s carbon footprint.

The study was published in Joule and demonstrates how renewable energy can be used more efficiently to produce fuel and other materials. The team’s work highlights the exciting possibilities of electro-biodiesel as a cleaner, greener alternative to conventional fuels.

Source: Washington University in St. Louis.