Scientists have developed a new method to make key components for future fuel cells more efficiently.

This new process could significantly lower the production cost of next-generation protonic ceramic cells (PCCs), which are emerging as a promising technology for clean energy.

The research, published in Advanced Energy Materials, shows how the new method could help make fuel cells cheaper and more effective.

Today, many solid oxide cells (SOCs) are used to generate electricity and produce hydrogen, but they require high temperatures—over 600°C—to operate.

While this makes them efficient, it also raises their production cost and leads to wear and tear over time.

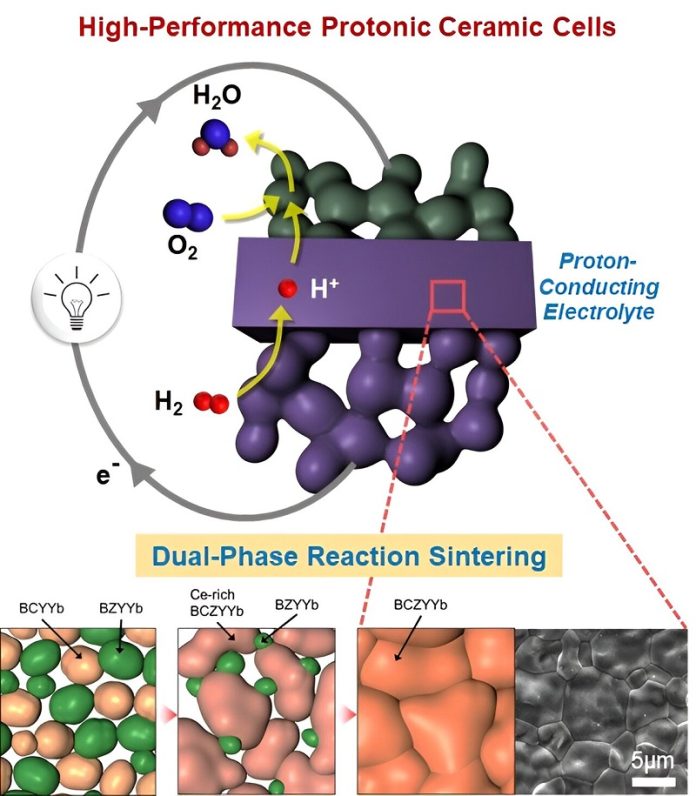

Protonic ceramic cells (PCCs) are seen as the next big thing in energy conversion because they use hydrogen ions (protons) instead of oxygen ions, which can make them even more efficient at lower temperatures.

However, producing the electrolytes that make PCCs work requires a process called sintering, which involves heating the materials to extremely high temperatures, often over 1,500°C.

These high temperatures can damage the materials and reduce their performance, which has been a major challenge in developing PCCs for widespread use.

The research team, led by Dr. Ho-Il Ji from the Korea Institute of Science and Technology (KIST) and Professor Sihyuk Choi’s team from Kumoh National Institute of Technology, found a way to lower the sintering temperature to 1,400°C.

They developed a new process that combines two different compounds to create an electrolyte with excellent sintering properties, without the need for additives.

This method allows the materials to form a dense, high-quality membrane at lower temperatures, which improves the overall performance of the fuel cell.

The new electrolyte produced through this process demonstrated a significant increase in power density—about twice that of current cells—when tested in proton ceramic cells. This could lead to shorter production times, better performance, and greater thermal stability in the fuel cells.

This breakthrough could also pave the way for the mass production of large-area fuel cells, which are needed for commercial applications.

If successful, this new technology could help support green hydrogen production for clean energy and even use waste heat from nuclear power plants for energy production.

Source: KSR.