Researchers from Zhejiang University, led by Prof. Kaichen Xu, have developed a new laser technique to solve the issue of copper oxidation in sensor systems.

This breakthrough could lead to safer and longer-lasting equipment in industries like aerospace, automotive, healthcare, and transportation.

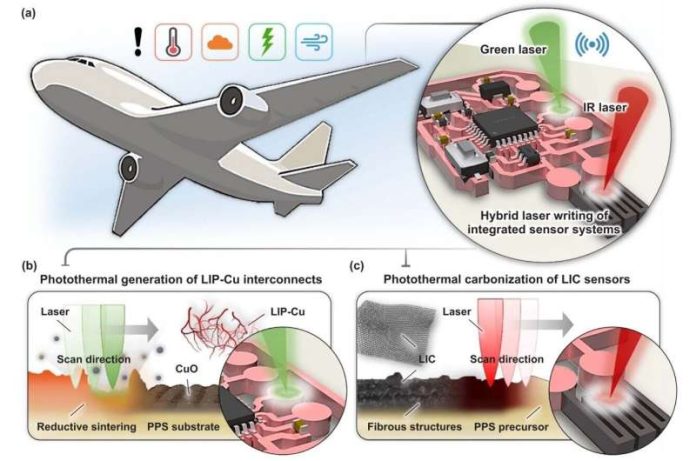

The team’s research, published in the International Journal of Extreme Manufacturing, introduces a hybrid laser direct writing method that allows copper and carbon-based sensors to be integrated into engineering thermoplastics.

These materials are used in many critical devices, and this new technique enables real-time temperature monitoring, which helps ensure optimal performance and reliability over time.

The Xu research group specializes in creating flexible electronics that can be used in extreme environments or in wearable and implantable devices.

Their work focuses on developing new manufacturing techniques and multifunctional devices by using hybrid laser platforms, which can perform multiple tasks.

The copper oxidation problem

Copper (Cu) is an essential part of sensor systems because it’s highly conductive and cost-effective.

However, it easily oxidizes during and after processing, which affects its durability. Copper oxidation can reduce the efficiency and lifespan of the sensors, making them less reliable over time.

To overcome this issue, Prof. Xu’s team developed a one-step photothermal treatment that makes copper resistant to oxidation, even at high temperatures of up to 170°C. This process ensures that copper can last longer without degrading, making it ideal for use in extreme conditions.

The hybrid laser process

The researchers’ new method consists of two main steps:

- Creating Copper Interconnects: They used a continuous wave (CW) laser to perform photothermal reduction and passivation of copper oxide (CuO). This step helped to create highly durable copper interconnects that are resistant to oxidation.

- Forming Carbon-Based Sensors: The team used an infrared (IR) laser to create laser-induced carbon (LIC) sensors from the thermoplastic substrate. These sensors can monitor temperature and other environmental conditions in real time.

The process allowed the simultaneous reduction, sintering, and passivation of copper, making it more resistant to high temperatures. The sensors created through this process were tested for their ability to monitor temperature under different conditions, proving to be durable and reliable.

Potential applications

This new laser technique has the potential to be used in a wide range of industries, including aerospace, automotive, high-speed trains, and medical devices.

The integrated sensor system offers a lightweight, long-lasting solution for monitoring temperature and other environmental factors in real time.

Prof. Xu’s team is also working on expanding the system to monitor additional factors such as pressure, strain, and humidity.

Their ultimate goal is to develop advanced techniques for producing high-quality electronics that can be used on curved surfaces, which would allow for even more flexible and innovative applications.

This breakthrough brings us one step closer to better, more durable sensors that can operate in extreme environments, providing important safety and performance benefits across various industries.

Source: KSR.