Engineers at Princeton University have taken inspiration from oyster and abalone shells to develop a new cement composite that is much stronger and more flexible than regular cement.

This new material is 17 times more resistant to cracking and 19 times more capable of stretching without breaking.

Their findings could help make various brittle materials, like concrete and porcelain, more durable.

Shashank Gupta, a graduate student in Reza Moini’s lab at the Department of Civil and Environmental Engineering, explained, “If we can engineer concrete to resist crack propagation, we can make it tougher, safer, and more durable.”

In a study published in Advanced Functional Materials, Moini’s team reported that creating alternating layers of cement paste and thin polymer significantly increases the material’s crack resistance and flexibility.

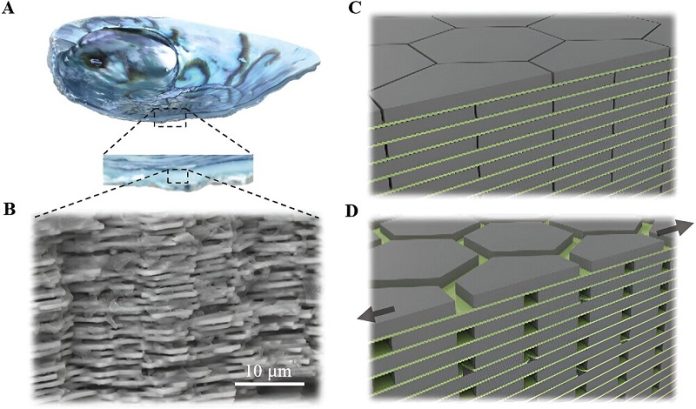

This innovative approach was inspired by nacre, also known as mother of pearl, which lines the inside of certain shells.

Nacre is made up of hexagonal tablets of aragonite, a hard mineral, glued together by a soft biopolymer. The hard aragonite provides strength, while the soft biopolymer adds flexibility and resistance to cracks.

When stress is applied, the aragonite tablets can slide past each other, which helps dissipate energy and prevent breaking.

This combination of hard and soft components makes nacre incredibly strong and resilient.

Gupta emphasized, “This synergy between the hard and soft components is crucial to nacre’s remarkable mechanical properties.”

To mimic nacre, the Princeton team used Portland cement paste, a common construction material, combined with a small amount of polymer. They created multi-layered beams by alternating sheets of cement paste with layers of polyvinyl siloxane, a highly stretchable polymer.

These beams were then tested to measure their resistance to cracking.

The researchers experimented with three types of beams. The first type consisted of alternating layers of cement paste and thin polymer. For the second type, they used a laser to engrave hexagonal grooves into the cement paste sheets, then stacked these grooved sheets with polymer layers in between.

The third type was similar but involved completely separating the hexagonal sections of cement paste and connecting them with the polymer layer, resembling the structure of nacre more closely.

These three types were compared against a solid, unlayered cement paste. The results showed that the layered composites were significantly tougher and more flexible than the solid cement.

By looking to nature, the Princeton team has developed a stronger and more durable cement composite that could improve the longevity and safety of many construction materials in the future.