Have you ever dropped a mug or sat on your glasses?

If so, you might not have noticed the complex patterns of cracks that appeared.

Yet, these intricate designs are what John Kolinski and his team at the EMSI laboratory in EPFL’s School of Engineering are fascinated by.

They study how cracks spread through materials to help create safer and more durable materials for buildings, sports equipment, and airplanes.

Traditionally, experts thought cracks just spread across surfaces in a simple, flat pattern. However, Kolinski’s team found that cracks often dive deep, forming 3D networks filled with ridges and other complicated shapes.

Capturing these patterns as they happen is tricky because materials aren’t see-through and cracks form very quickly.

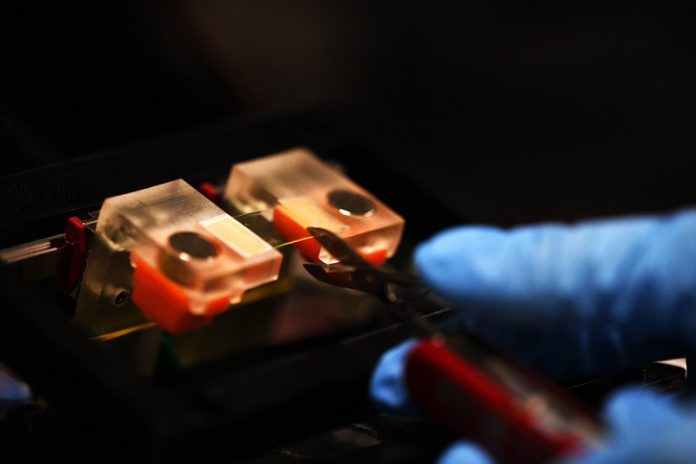

But with a Swiss Army knife and a special microscope, Kolinski’s group has managed to watch these complex crack formations in real time.

What’s more, they’ve discovered that the more complicated the crack, the tougher the material becomes. This is because it takes more energy to push a complex crack forward than a simple, straight one.

This discovery is quite a breakthrough.

It suggests that materials can be made stronger by allowing cracks to form in more complex patterns, challenging the traditional belief that cracks are purely negative.

Their research, which has been shared with the world through Nature Physics, uses hydrogels and an elastomer to mimic how cracks form in glass and plastics, or rubbery materials, respectively.

By cutting very thin slices of these materials and then watching how cracks developed under a microscope, the team has been able to understand better how cracks grow and what makes materials strong or weak.

They saw that the energy needed to make a crack move was directly linked to the length of the crack’s tip—the more complex the crack, the more energy needed.

In one of their experiments, they even showed how a crack changes its path when it hits a hard spot inside the material, becoming more complex and requiring more energy to keep going. This finding could lead to new ways of designing materials that are stronger and more resistant to breaking.

Kolinski emphasizes the importance of recognizing the role of crack geometry in material testing. Ignoring the 3D nature of cracks could lead to dangerously overestimating a material’s toughness.

This insight opens up new possibilities for material design and highlights the need for precise testing methods to ensure safety and reliability in materials used in everyday life and advanced engineering applications.