Scientists from the Massachusetts Institute of Technology (MIT) and Duke University have stumbled upon an interesting finding: introducing weaker bonds into a material can actually make it stronger.

In a groundbreaking study, they worked with a certain type of polymer, or a large molecule made up of repeating units, and found that incorporating some weaker links actually increased its resistance to tearing by up to ten times.

These polymers, known as polyacrylate elastomers, are usually used in car parts and as ‘ink’ for 3D-printed items.

A tenfold increase in strength could revolutionize industries, and if this concept can be applied to things like rubber tires, we could see tires that last longer and create less microplastic waste.

Jeremiah Johnson, an MIT chemistry professor, explains that this unusual method of strengthening a material doesn’t seem to change any other physical aspects of the polymer.

That’s quite an achievement, as typically, attempts to toughen materials result in other unwanted changes.

This discovery stems from prior research done by Johnson, Stephen Craig, a Duke University chemistry professor, Michael Rubinstein, another Duke University professor, and MIT Professor Bradley Olsen.

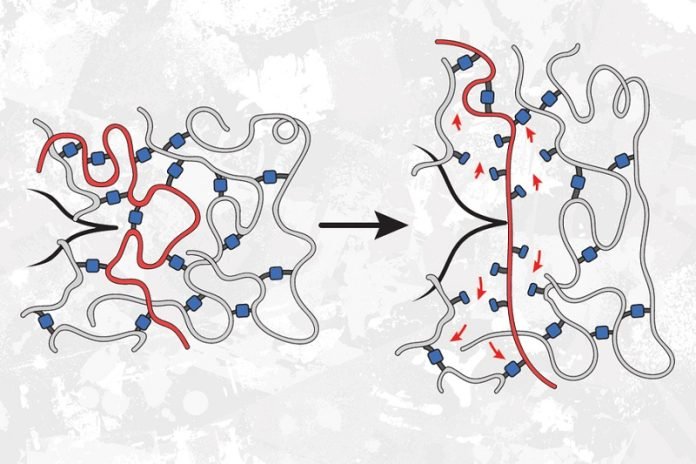

They examined star polymer networks, which are built kind of like a volleyball net, with ‘linkers’ joining the end of each arm of a star-shaped structure. In their 2021 study, they observed that weaker linkers made the material less robust, which was expected.

However, when they altered the design of the polymer network and used weaker linkers to join the repeating units in random locations, they noticed something remarkable. The material became a lot tougher to tear apart.

They believe this happens because cracks moving through the material prefer to travel through the weaker bonds. Even though the weaker bonds break more easily, the path through them is longer, and the crack has to break more bonds overall, making the material more tear-resistant.

In their tests, these fortified polymers, which used weaker linkers for only about 2% of the material, were nine to ten times tougher to tear than those made with stronger connectors. Interestingly, they noticed that this didn’t change any other properties of the material, such as its heat resistance.

The team is now exploring the potential of this approach to improve the toughness of other materials like rubber.

Their research is part of a broader mission of the National Science Foundation-funded Center for the Chemistry of Molecularly Optimized Networks, which aims to understand how molecular components of polymer networks influence their physical behavior.