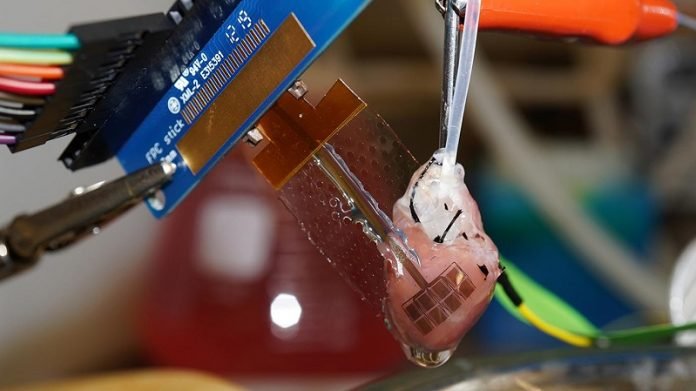

Bringing together soft, malleable living cells with hard, inflexible electronics can be a difficult task.

UChicago researchers have developed a new method to face this challenge by utilizing microscopic structures to build up bioelectronics rather than creating them from the top down—creating a highly customizable product.

Researchers are very interested in creating electronics that can interface seamlessly with biological tissues; these could be used as tools to investigate how cells and tissues work or as medical devices—such as tissue stimulations to treat Parkinson’s disease or cardiac problems.

Typically, such bioelectronics are created through a “top-down” approach, with the electronics already put together and made smaller to fit with the biological system.

But in a new study published in Nature Nanotechnology, Assoc. Prof. Bozhi Tian and his team use a different method.

The researchers took a “bottom-up” approach, in which small building blocks called micelles come together to form carbon-based bioelectronics.

Micelles are a collection of molecules that can form a spherical structure due to interactions with water.

These unique structures play an integral role in many important biological and chemical processes, such as how detergents remove oils, or how the body processes certain fats.

The small micelles come together to form very thin sheets that are nanoporous—covered with extremely tiny holes—that allows for much more flexibility. These pores increase the surface area, allowing more contact and a better interface.

The pores also improve the flexibility of the bioelectronic device, which is important because the bioelectronic needs to be able to fit well with the soft biological membrane.

To understand this, imagine the malleability of a slice of cake with its many air pockets, versus a dense brownie.

“This is the very first research paper that uses micelle-driven microscopic self-assembly for bioelectronics,” said Aleksander Prominski, a chemistry graduate student and co-first author of the paper.

“It also suggests that we should look for more principles from other fields, such as energy storage, to construct biointerfaces.”

Another positive to this approach is the versatility in building the device. Creating the bioelectronics is as simple as swapping out the building blocks.

“Our porous carbon membranes are capable of biophysical sensing and stimulation,” said Lingyuan Meng, a graduate student from the Pritzker School of Molecular Engineering and co-first author on the paper.

“This technology could find clinical applications as well to address conditions such as epilepsy or Parkinson’s.”