Researchers at Kaunas University of Technology (KTU) in Lithuania have found an innovative way to turn unwanted clothing into something extremely useful: stronger, more sustainable cement.

Their work shows how waste from the textile industry—one of the world’s biggest polluters—can help make construction materials that are tougher and better for the environment.

Across Europe, billions of tons of waste are produced every year, and both the textile and construction industries contribute heavily to this problem.

Clothing waste is especially difficult to manage because most fabrics are mixed materials and contain dyes, coatings, and other additives.

Only a small portion of used clothing is collected for recycling, and an even smaller fraction is turned into new textiles. Most old garments are burned or buried in landfills, creating pollution and releasing microplastics.

Because recycling clothing into new fibers is still technically challenging, scientists are looking for other high-value uses for discarded textiles.

One promising area is the cement and concrete industry, which relies on energy-intensive processes and produces large amounts of CO₂. Researchers believe that incorporating textile waste into cement could reduce emissions and improve the performance of building materials.

According to Dr. Raimonda Kubiliūtė from KTU’s Faculty of Chemical Technology, reducing the amount of ordinary Portland cement used in construction is essential for lowering environmental impact.

Many research teams worldwide are trying to replace part of the cement with alternative materials—such as industrial waste—without weakening the final product.

KTU researchers recently published a study showing that waste clay materials can successfully replace a portion of traditional cement while maintaining strong performance.

Building on that idea, the team also experimented with textile waste, and the results were impressive.

When small amounts of recycled polyester fibers from discarded clothing were mixed into concrete, the material became 15% to 20% stronger.

It also handled extreme temperature changes better, showing improved resistance to freeze–thaw cycles. This means buildings and structures made with such concrete could last longer in harsh climates.

The team went further by heating textile waste to 300°C in an oxygen-free environment.

This process produced carbon-rich granules with high energy potential, which could be used as an alternative fuel. Burning this fuel leaves behind ash—and KTU researchers discovered that this ash can also strengthen cement.

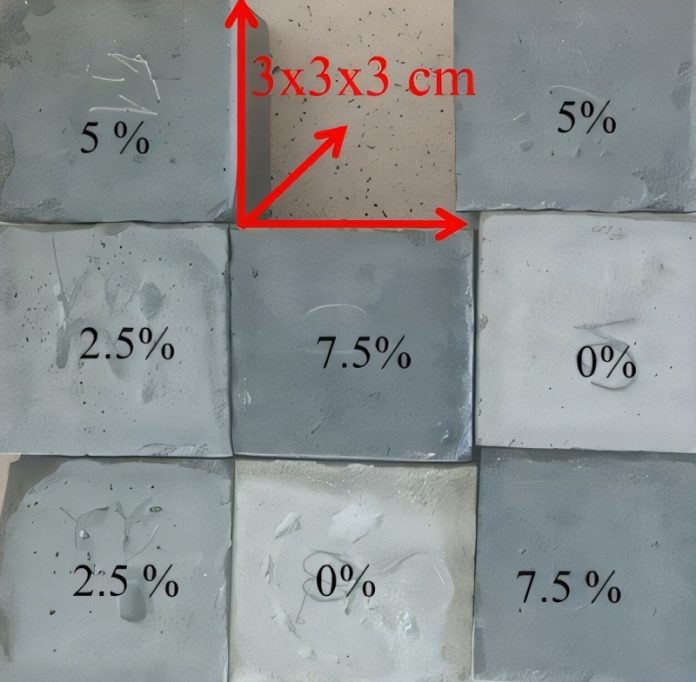

Their tests found that replacing up to 7.5% of ordinary cement with textile ash increased the compressive strength of the material by as much as 16%. This approach not only reduces waste sent to landfills but also cuts down CO₂ emissions during cement production.

Dr. Kubiliūtė says the technology is still in its early stages, but its potential is clear.

Turning old clothing into fuel and stronger cement could help solve two environmental problems at once—waste from the fashion industry and pollution from construction—while moving Europe closer to a circular, sustainable economy.