As electric vehicles become more common, the number of used batteries piling up around the world is rapidly increasing.

Recycling these batteries efficiently is a major challenge because lithium—the key ingredient in most EV batteries—is expensive to mine and refine.

Current recycling methods often rely on smelting or dissolving shredded battery waste in strong acids, which use large amounts of energy and produce chemicals that need further processing before they can be reused.

Now, engineers at Rice University have come up with a cleaner and simpler way to recover lithium.

Instead of burning or dissolving the waste, their method uses the same chemistry that powers a battery—recharging—to extract lithium directly from used materials.

The approach, which they call “recharge-to-recycle,” allows lithium ions to move into water, where they combine with hydroxide to form lithium hydroxide, a compound that can go straight back into new battery production.

“We asked a basic question: if charging a battery pulls lithium out of the cathode, why not use that same reaction to recycle?” said Sibani Lisa Biswal, chair of Rice’s Department of Chemical and Biomolecular Engineering and senior author of the study, published in Joule.

“By pairing that chemistry with a compact reactor, we can separate lithium cleanly and make the exact product manufacturers need.”

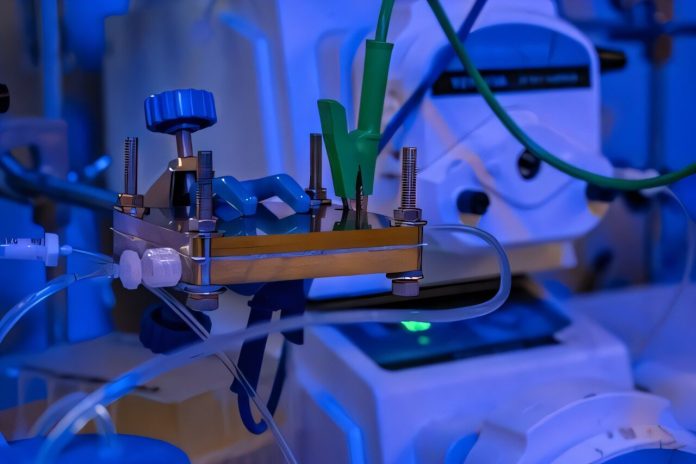

The process takes place in a small electrochemical reactor that requires only water, electricity, and battery waste. As the system “charges” the spent cathode material, lithium ions travel through a thin membrane into a stream of water.

There, they meet hydroxide ions created from splitting water molecules. The two combine to form high-purity lithium hydroxide—no harsh acids or complex chemicals required.

Tests showed that the method is remarkably energy efficient. In one mode, it used just 103 kilojoules of energy per kilogram of waste—about ten times less than traditional acid-based recycling methods.

The lithium hydroxide produced was over 99% pure, good enough to be used directly in new batteries. The system also proved durable, recovering nearly 90% of the lithium over 1,000 hours of continuous operation.

Co-author Haotian Wang, associate professor of chemical and biomolecular engineering, said the breakthrough could make battery recycling cleaner and cheaper. “Directly producing lithium hydroxide means fewer steps, less waste, and a stronger supply chain,” he said.

The team also demonstrated that the process works on multiple types of batteries, including lithium iron phosphate and nickel-manganese-cobalt variants. In one experiment, they even processed whole battery electrodes directly from aluminum foil, showing the system could fit into automated recycling lines.

“Now that we’ve made lithium extraction cleaner and simpler,” Biswal said, “the next challenge is concentrating and crystallizing the lithium hydroxide efficiently. Solving that could make battery recycling truly sustainable.”

Source: Rice University.