In the 1980s, when micro-electro-mechanical systems (MEMS) were first invented, engineers imagined a future where robots could be shrunk to microscopic sizes.

Smaller robots promised faster movement, greater precision, and entirely new applications. But reality proved far more difficult.

Building complex 3D machines at microscopic scales requires manufacturing techniques far beyond traditional tools. For decades, this dream remained out of reach.

Now, nearly 50 years later, researchers have taken a major step forward. PhD students Steven Man and Sukjun Kim, working with Professor Sarah Bergbreiter at the University of Maryland, have developed a new 3D nanofabrication method that allows them to build some of the smallest and fastest robots ever made.

Their research, published in Science Robotics, shows how new 3D printing technologies can finally unlock the potential of microscale robotics.

The team focused on creating miniature versions of Delta robots—a type of industrial robot known for its speed and precision.

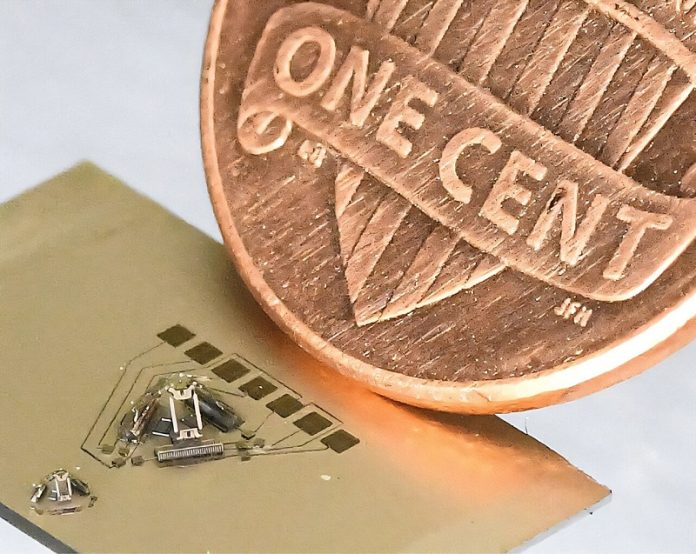

Full-size Delta robots, usually a few feet tall, are commonly used in factories for sorting, picking, and assembling small parts. Man and Kim designed micro-scale versions called microDeltas, measuring just 1.4 millimeters and 0.7 millimeters tall—small enough to fit on a grain of rice.

Past attempts to build micro-robots often required manually folding tiny components or assembling microscopic parts by hand, a slow and delicate process. The new method avoids this entirely.

Instead, the researchers use two-photon polymerization, a state-of-the-art 3D nanoprinting technique where a tightly focused laser hardens photosensitive material with extraordinary precision—allowing structures to be built layer by layer at the scale of hundreds of nanometers.

After printing, the team coats the robot with a thin layer of metal to create electrical connections and enable movement, all without any manual assembly.

The results are remarkable. The microDelta robots are the smallest and fastest Delta robots ever created, operating at speeds over 1,000 cycles per second. Their tiny size gives them incredible precision—accurate to less than one micrometer—and surprisingly strong performance. In demonstrations, one robot was able to launch a grain of salt into the air. That grain was 7.4% of the robot’s entire body weight, showing how powerful these tiny systems can be.

An important advantage of this new fabrication approach is how quickly designs can be tested and improved. Man was able to complete eight full generations of microDelta robots in a short period of time, something that would have taken months using older methods. This rapid design cycle will make it easier for future students and researchers to refine the robots even further.

Because microDeltas are so small, researchers envision creating dense arrays of them working together. These could enable highly sensitive haptic devices, intricate micromanipulation tasks, or new forms of minimally invasive medical tools.

According to Professor Bergbreiter, removing the need for assembly is transformative. At small scales, assembling tiny motors and mechanical parts is nearly impossible. By directly printing working robots, scientists can finally explore what truly miniaturized machines can do.

This breakthrough marks a significant milestone in the long-awaited field of micro-robotics, opening the door to powerful, fast, and incredibly small robots that may soon play important roles in medicine, manufacturing, and advanced sensing technologies.