As global energy demands soar—driven by data centers powering artificial intelligence, expanding industries, and ever-growing electricity needs—scientists are racing to make energy systems more efficient.

One team at the U.S. National Renewable Energy Laboratory (NREL) believes they’ve taken a major step forward with a groundbreaking new device called ULIS, short for Ultra-Low Inductance Smart power module.

Power modules are the building blocks that control how electricity flows between systems, from data centers to airplanes.

The ULIS module is different because it combines record-setting efficiency with low-cost manufacturing, packing more power into a smaller and lighter package than ever before.

Built with silicon carbide semiconductors, ULIS delivers five times greater energy density than older designs while reducing parasitic inductance—the main obstacle to fast, efficient electrical conversion—by as much as ninefold.

The result is a compact, reliable module that squeezes more usable energy out of every watt of electricity.

The device operates at 1200 volts and 400 amps, making it suitable for high-demand applications like next-generation aircraft, power grids, heavy-duty vehicles, and even future fusion reactors.

Perhaps most impressively, ULIS can monitor its own condition and predict potential failures before they happen.

For aviation or military vehicles, where reliability is critical, this self-checking ability could make a life-or-death difference.

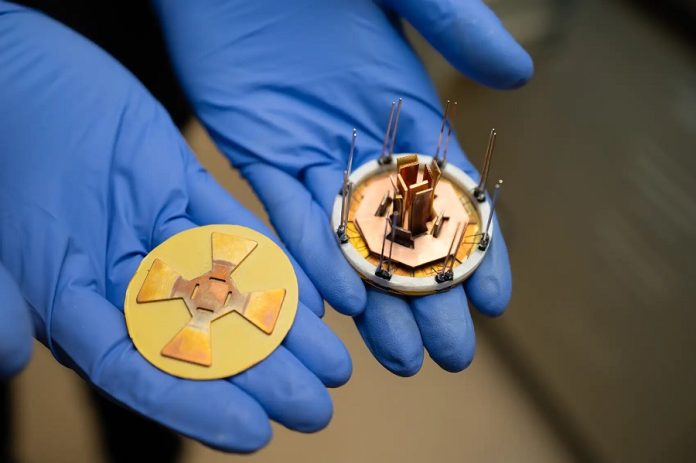

The breakthrough lies in its design. Traditional power modules house components inside bulky, brick-shaped packages, which create inefficiencies and add weight. The ULIS team instead flattened the design into a nearly two-dimensional octagon, which allows better current flow and cancels out magnetic interference.

As one researcher described it, they “squished it flat, like a pancake,” creating a design that is not only high-performing but also easier and cheaper to fabricate.

Instead of relying on rigid ceramic bases, the researchers bonded copper sheets to a flexible polymer called Temprion.

This makes the module thinner, lighter, and less costly to manufacture—hundreds rather than thousands of dollars. Another innovation is its wireless control system, which eliminates the need for external cables and allows ULIS units to be slotted into machines like Lego pieces.

While today’s ULIS modules run on silicon carbide semiconductors, the design is “future-proofed.” It can easily adapt to next-generation materials such as gallium nitride or gallium oxide, which may power the electronics of tomorrow.

The potential impact is enormous. ULIS could modernize power grids by delivering electricity more efficiently, enable advanced electric aircraft to become commercially viable, and one day support fusion reactors that provide clean, limitless energy.

As Faisal Khan, NREL’s chief power electronics researcher, put it: “We consider ULIS to be a true breakthrough. It’s a future-proofed, ultrafast power module that will make the next generation of power converters more affordable, efficient, and compact.”