A team of scientists led by Lawrence Livermore National Laboratory (LLNL) has developed a remarkable new soft material that can absorb strong impacts, change shape with heat, and bounce back after being hit—without breaking.

This “programmable” material could one day be used in protective gear, flexible robots, aerospace parts, and even biomedical devices that move with the body.

The material is made from something called liquid crystal elastomers, or LCEs.

These are rubbery materials that can respond to heat, light, or stress by changing their shape.

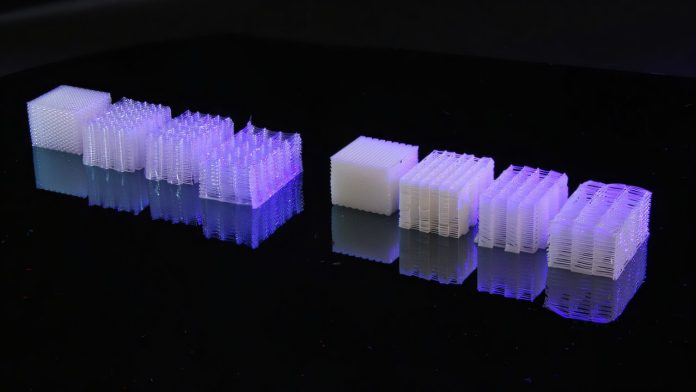

What makes this discovery special is how the scientists shaped the LCEs into lightweight, flexible structures using 3D printing.

By doing this, they created smart materials that can stiffen or soften, absorb shock, and even reshape themselves on demand.

Rodrigo Telles, the lead author of the study, said the most exciting part is the level of control they now have—from tiny molecules to the final structure.

This means the team can design materials that behave exactly the way they want, depending on the environment they’re used in.

Traditional materials like foam or silicone are set in their properties once they’re made. But these new LCE structures act differently.

Their inner molecules can shift and rearrange under pressure, allowing the material to stretch, bend, or absorb energy in a way that feels almost alive.

During testing, these LCE lattices were soft and flexible under slow pressure but incredibly tough under fast, high-speed impacts. In fact, they absorbed up to 18 times more energy than similar silicone materials—and they didn’t break, even after repeated impacts.

Elaine Lee, another researcher on the team, explained that when the material is hit hard, its internal molecules quickly reorient themselves.

Instead of cracking, the energy spreads across the entire structure. That’s why the material stays strong and bounces back, making it much more durable than typical rubbery substances.

To achieve these results, the team used a special 3D printing method that aligns the LCE molecules like muscle fibers as they print. This built-in direction allows the material to shrink in one direction and expand in another when heated—basically programming it to change shape in specific ways.

They also created computer models to predict how the material will behave when heated or hit. These simulations help guide future designs and improve the performance of the material even further.

The team plans to keep exploring more advanced shapes and applications.

Their ultimate goal is to create smart materials that respond to real-world conditions—like body armor that adapts in real time or medical devices that move with the human body, offering both flexibility and strength.

Source: Lawrence Livermore National Laboratory.