Scientists at the University of California San Diego have come up with a straightforward but powerful way to predict problems in lithium metal batteries, using a common imaging tool called scanning electron microscopy (SEM).

This breakthrough could help create safer, longer-lasting, and more powerful batteries for electric cars, laptops, phones, and large-scale energy storage.

The study, published in Proceedings of the National Academy of Sciences, focuses on lithium metal batteries, which can store about twice as much energy as the lithium-ion batteries used today.

That extra energy could mean electric cars travel twice as far on a single charge and devices run much longer before needing to be plugged in.

However, there’s a major challenge holding them back—how lithium deposits form on the battery’s electrodes during charging and discharging.

If lithium deposits spread out evenly, the battery can last a long time.

But when the deposits grow unevenly, they can form tiny needle-like shapes called dendrites.

These dendrites can pierce the battery’s separator, causing dangerous short circuits and sudden failure.

Until now, scientists have mostly judged the evenness of lithium deposits just by looking at microscope images and describing them with words like “chunky,” “mossy,” or “whisker-like.” This approach is subjective, meaning that what one lab considers “uniform” might look different to another.

To solve this problem, Ph.D. student Jenny Nicolas and her team, led by Professor Ping Liu, created a simple algorithm that turns these images into a measurable score.

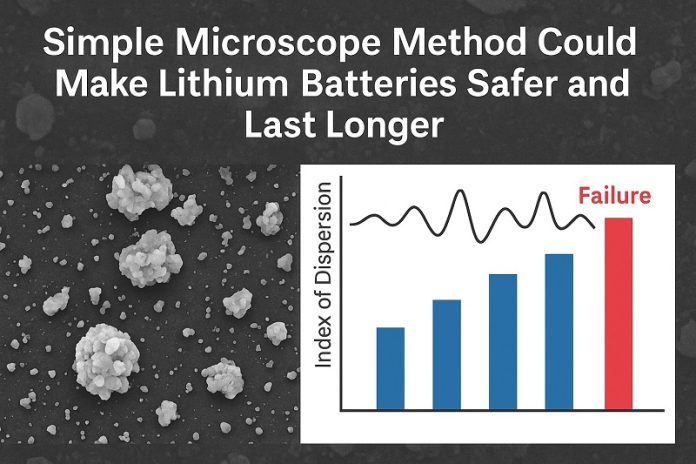

They used SEM because it can capture detailed pictures of battery electrodes, showing their 3D texture in a flat, black-and-white image.

Here’s how it works: scientists take SEM images of the battery electrodes and convert them into black-and-white pixels. White pixels represent the highest points of lithium deposits, while black pixels show the background or inactive areas.

The image is then divided into sections, and the program counts the white pixels in each one. From this, it calculates something called the “index of dispersion” (ID).

The ID is a number that shows how evenly the lithium is spread. A score closer to zero means the deposits are very uniform, while a higher number means they are more uneven and clumped together.

The team tested their method on thousands of synthetic images with known particle distributions, confirming it worked accurately.

They then applied it to real battery images and found that the ID consistently increased as the batteries aged, showing deposits were becoming less uniform. Interestingly, sudden spikes and drops in the ID appeared just before the batteries failed—acting like an early warning sign for problems.

Because most battery researchers already use SEM, this method could be easily adopted without extra equipment.

As Nicolas put it, “Our tool is a low-hanging fruit for researchers—it helps make the most of the data they’re already collecting.”