Imagine being able to clean carbon dioxide directly from the air using only as much electricity as it takes to charge your phone.

That is exactly what a team of researchers from KAIST and MIT has achieved with a new fiber-based technology that could transform the future of carbon capture.

Direct air capture (DAC) is a process that removes CO₂ from the atmosphere, even though its concentration is very low—just a few hundred parts per million.

It’s an important tool in the fight against climate change because it doesn’t just prevent emissions, it can actually achieve “negative emissions” by pulling carbon out of the air we breathe.

But until now, the technology has faced one major obstacle: energy costs.

Traditional DAC systems rely on hot steam, usually above 100℃, to regenerate their materials and release the captured CO₂.

This stage consumes about 70% of the total energy, requiring large, complex heat-exchange systems. The high costs have made DAC difficult to commercialize.

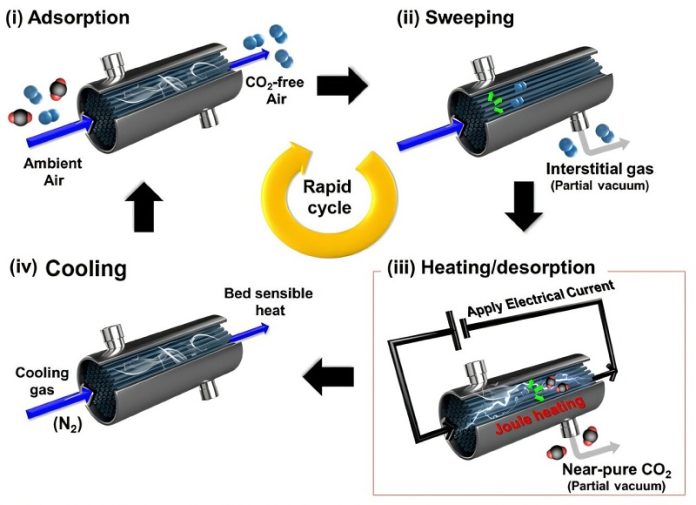

The new approach, called e-DAC (Electrified Direct Air Capture), solves this problem with conductive silver nanofibers that heat themselves using electricity.

Instead of heating a large chamber, the fibers generate heat directly through a process called Joule heating—the same principle behind an electric blanket.

This method reduces wasted energy and allows for precise, localized heating.

The results are striking. The fibers can heat up to 110℃ in just 80 seconds using only 3 volts—the same voltage used to charge a smartphone.

This makes the system not only highly efficient but also practical in low-power environments, especially when paired with renewable energy sources such as solar or wind.

The researchers showed that their system can recover more than 95% high-purity CO₂ while reducing unnecessary heat loss by about 20% compared to existing methods.

The key to the breakthrough lies in the unique structure of the fibers. The team coated porous fibers with an ultra-thin layer—only about three micrometers thick—made of silver nanowires and nanoparticles.

This coating provides excellent electrical conductivity while leaving enough open space for CO₂ molecules to flow freely through the fibers. The result is uniform, rapid heating combined with smooth gas diffusion, making the process both effective and scalable.

When multiple fibers were connected in parallel, the system proved even more efficient, with electrical resistance dropping below 1 ohm. This demonstrates that the technology can be scaled up for larger industrial systems.

The research, published in Advanced Materials, is the culmination of five years of work.

Patent applications were filed as early as 2022 in the US, Europe, Japan, Australia, China, and beyond, showing that the technology has been developed with real-world commercialization in mind.

According to Professor Dong-Yeun Koh of KAIST, the innovation is more than just a way to reduce emissions.

“DAC is a key means of achieving negative emissions by purifying the air itself,” he explained.

With its low energy use and compatibility with renewables, this fiber-based system could help industries and cities worldwide move closer to their carbon-neutral goals.