Scientists at The University of Texas at Austin have developed an exciting new 3D printing method that blends soft and hard materials into one seamless object.

Inspired by how nature combines flexible and tough materials—like how cartilage and bone work together in the human body—the team has created a process that could change how we make prosthetics, medical devices, and flexible electronics.

The key to this breakthrough is light. The researchers designed a special liquid resin and used two different colors of light to cure it into solid materials with very different properties.

When violet light is used, the resin turns into a soft, rubbery material.

But when ultraviolet (UV) light is used, it becomes strong and rigid like hard plastic. With this method, both soft and hard zones can be created at the same time during printing, all in a single object.

One of the biggest problems with combining different materials is that they often come apart at the connection point.

For example, think about how the rubber sole of a shoe can peel away from the fabric upper over time.

This new method solves that problem by designing a molecule that helps the two types of materials bond more strongly.

It also allows the team to create a smooth transition between soft and hard parts, instead of a sharp dividing line, making the object much stronger and more durable.

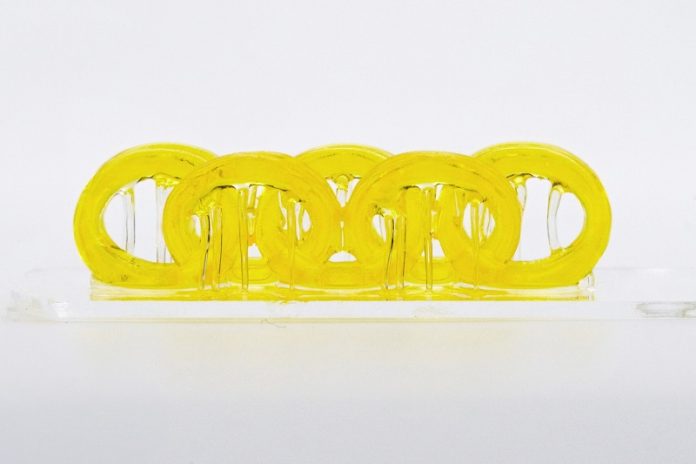

To test the new system, the researchers printed a small, working model of a human knee joint. It had rigid “bones” and flexible “ligaments” that moved smoothly together—just like a real knee. They also made a stretchable electronic device with a gold wire.

The soft areas could bend and stretch, while a rigid zone kept the circuit from breaking.

What’s even more impressive is that the process works quickly and with great detail. The equipment used is relatively simple and not too expensive, which means hospitals, schools, and research labs might be able to use it in the near future.

According to chemistry professor Zak Page, who led the study, this approach offers a new level of freedom for designers and engineers. It could be used to make wearable health devices, soft robots, surgical models, and more.

In short, this light-based 3D printing method opens up new possibilities for making complex, flexible, and durable objects that mimic how nature builds things—blending strength and flexibility exactly where it’s needed.

Source: University of Texas at Austin.