A team of researchers from Michigan State University has found a surprising way to make lithium-ion batteries safer and longer-lasting—by using a natural material found in wood.

Lithium-ion batteries power everything from smartphones to laptops and electric vehicles. But they can sometimes be risky.

If the inside of a battery gets too hot, it can lead to a short circuit, fire, or even an explosion. That’s why scientists are constantly looking for ways to make batteries safer.

In this study, engineering professor Chengcheng Fang teamed up with Mojgan Nejad from the College of Agriculture and Natural Resources.

Together, they turned their attention to lignin—a natural substance in wood that gives trees their strength.

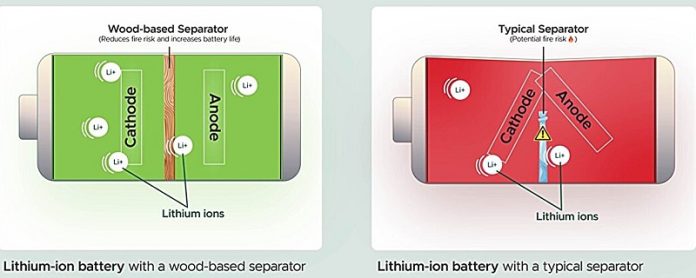

They discovered that lignin could be used to create a special thin film inside batteries, called a separator. This film sits between two parts of the battery—the positive and negative sides—to prevent them from touching and causing a short circuit.

Most commercial battery separators today are made from plastics that begin to shrink when they get hot, around 100°C.

This shrinking can make the battery more dangerous. But the lignin-based film remained stable up to 300°C, showing strong heat resistance and reducing the risk of short circuits and fire.

Even more impressive, the new wood-based film helped the battery last longer. Tests showed that batteries with this lignin film could be charged and used 60% more times compared to regular batteries. This means devices could have a much longer lifespan before the battery wears out.

Not only is the lignin separator safer and more efficient, but it’s also environmentally friendly. The team developed a dry manufacturing process that doesn’t use harmful chemicals and produces zero waste. They were able to make large amounts of the film using 100% of the raw materials, with no pollution.

Lignin is also easy to find and doesn’t need any extra treatment to work in batteries. One form of it, called lignosulfonate, is already used in other industries and is readily available. This makes it a practical, low-cost option for greener battery technology.

“This shows a new way to design battery materials that are safer, better for the environment, and easier to make,” said Fang.

The research has been published in Advanced Materials, and the technology is now patent pending through the MSU Innovation Center. With this breakthrough, the future of batteries might just be rooted in trees.