Scientists from Tianjin University have developed a groundbreaking new way to test micro-LED wafers without causing any damage.

This could be a big step forward for the next generation of high-quality screens used in TVs, smartphones, and other advanced displays.

Micro-LEDs are tiny light-emitting diodes that promise brighter, more energy-efficient, and longer-lasting displays than current technology.

But during manufacturing, even the tiniest defect can cause problems.

To keep quality high and costs low, manufacturers need to test these wafers early in the production process.

The challenge is doing this without damaging the delicate micro-LED surfaces.

Led by Professor Huang Xian, a research team from the School of Precision Instrument and Opto-electronics Engineering at Tianjin University created a “soft-touch” method to solve this problem.

Their study was published in Nature Electronics on June 13.

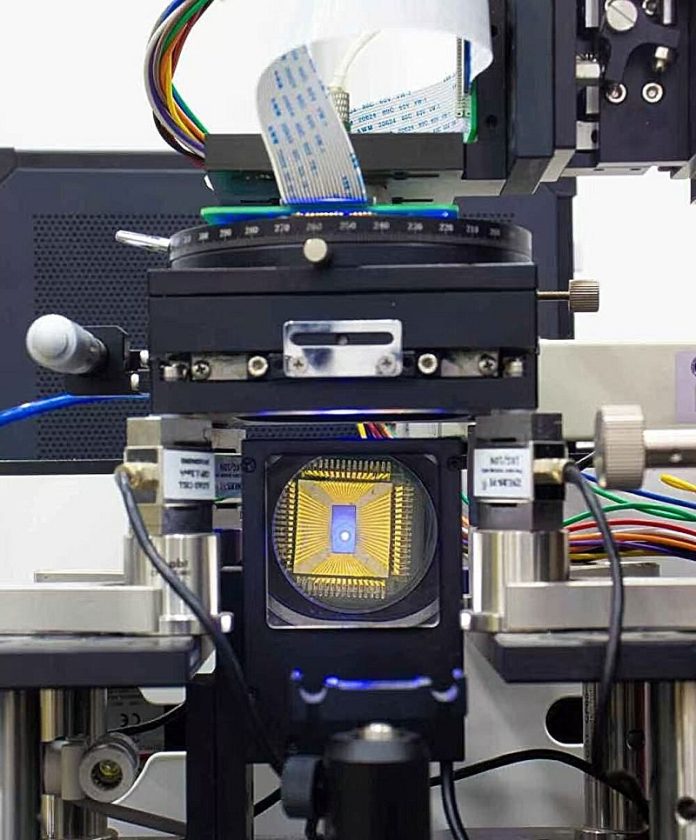

Instead of using rigid, sharp probes that press down hard and can scratch the surface, the team developed a flexible 3D probe array that lightly adapts to the shape of the micro-LED wafer.

These new probes apply a gentle pressure of just 0.9 megapascals—similar to the softness of a light breath. This allows for careful, high-speed electrical testing while keeping the wafer surface perfectly intact.

Professor Huang explained that the pressure from their flexible probes is only about one-ten-thousandth of what traditional rigid probes apply. As a result, not only is the wafer protected, but the probes themselves last longer. Even after one million testing cycles, the probes still function like new.

To make the system even more effective, the team also created a custom testing setup that works with the soft probes. This new combination gives manufacturers a powerful way to screen for defects and control quality without slowing down production or causing damage.

Huang described the discovery as a new foundation for the industry. It fills a major gap in how micro-LEDs are tested and opens the door to using this technology in other areas, such as advanced electronics and biophotonics—where sensitive biological materials are involved.

The technology is already moving toward real-world use through the Tiankai Higher Education Innovation Park. It offers a scalable, cost-effective solution for the fast-growing micro-LED market and shows how flexible electronics can play a role in solving delicate, high-tech challenges.