Researchers in Sweden have taken a major step forward in the search for clean energy by developing a new material that could make producing green hydrogen much more efficient.

The breakthrough comes from a team at Linköping University, led by Associate Professor Jianwu Sun, and it could help replace fossil fuels in vehicles that can’t easily run on batteries—like heavy trucks, ships, and airplanes.

Hydrogen is a clean fuel that produces only water when used, but most of the hydrogen we use today is made from fossil fuels.

This so-called “gray” hydrogen releases large amounts of carbon dioxide into the atmosphere—about 10 tons of CO₂ for every ton of hydrogen produced. That’s bad news for the climate.

What scientists really want is “green” hydrogen, which is made using renewable energy like sunlight. But current methods for making green hydrogen are not efficient enough or cost-effective on a large scale.

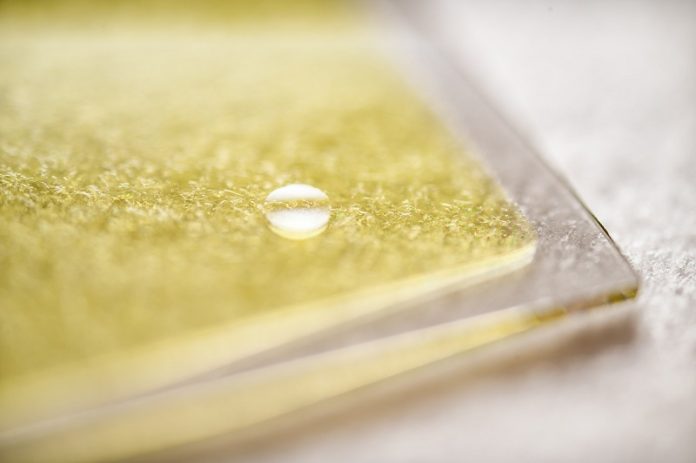

This is where the Swedish team’s new material comes in. It’s made of three layers: the first is cubic silicon carbide (3C-SiC), a material that can absorb sunlight well.

The second is cobalt oxide, and the third is a special catalyst that helps split water molecules into hydrogen and oxygen. When sunlight hits the material, it creates electric charges that power the reaction to split water into hydrogen fuel.

One big challenge in this process is keeping the positive and negative charges from canceling each other out before they can do their job.

The three-layered structure solves this by helping keep the charges separated, which makes the process much more efficient.

In fact, the researchers found that this new material is eight times more effective at splitting water than the original cubic silicon carbide on its own. That’s a huge improvement—and a sign that green hydrogen production using sunlight is becoming more realistic.

The goal is to reach an efficiency of at least 10% so that the technology can be used on a large scale.

Right now, most similar materials only achieve between 1% and 3%. Reaching 10% would mean green hydrogen could be produced affordably without needing extra electricity from other renewable sources.

Professor Sun believes it could take five to ten years of further research to reach that level, but this discovery is a big step in the right direction.

If successful, this technology could help provide a clean fuel source for the kinds of transportation that batteries can’t support—and that could make a big difference in the fight against climate change.