Imagine a single electronic device that can be both strong like plastic and soft like rubber, depending on how and where it’s used.

Thanks to a breakthrough from scientists in South Korea, that future may be closer than we think.

A research team from KAIST and Seoul National University has developed a special type of electronic ink that can be printed at room temperature to create circuits that change stiffness with temperature.

These printed circuits can switch between rigid and soft forms, opening the door to a new generation of flexible and adaptive electronics. This innovation could lead to smarter wearable health monitors, safer brain implants, and more responsive robots.

The secret behind this new technology lies in a metal called gallium. Gallium has a unique property: it is solid at room temperature but melts just below body temperature.

This means it can be used to create materials that are hard when needed but can become soft when warmed up, like when touching the skin.

However, printing with gallium has been very difficult. Its high surface tension and instability during melting have made it challenging to use in electronics—until now.

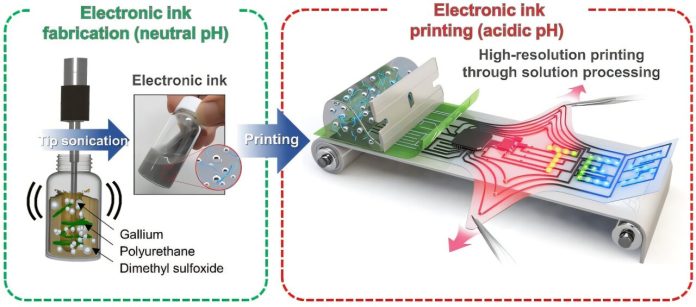

Led by Professors Jae-Woong Jeong, Seongjun Park, and Steve Park, the research team created a new kind of gallium-based ink. The key to their success was controlling the chemical environment of the ink using a common solvent called DMSO and carefully managing the ink’s pH (acidity level).

They mixed tiny gallium particles into a water-attracting plastic material called polyurethane, forming a thick and stable ink. When the ink is printed and gently heated, the solvent breaks down to create a mildly acidic environment.

This removes the surface oxide layer from the gallium particles, allowing them to merge into smooth, electrically conductive pathways.

The result is an ink that prints complex, high-resolution circuits—some as fine as a human hair—that conduct electricity extremely well and can shift between rigid and soft states. These circuits perform similarly to traditional printed circuit boards (PCBs) used in electronics today but with the added benefit of flexibility and adaptability.

The team has already shown how this technology could be used in real life. They printed a device that acts like a hard electronic gadget under normal conditions but becomes soft and flexible when worn on the skin, making it perfect for wearable health monitoring. They also built a brain implant that stays stiff for easy and precise insertion during surgery but softens once inside the brain, reducing damage and inflammation—a big step forward for safer medical devices.

This new approach to printing electronics could make it easier and cheaper to create smart, adaptable technologies. The ink works with existing printing methods, so it can be used to produce large, flexible devices at scale. According to Professor Jeong, the real success of this project is that it finally solves the problem of printing with liquid metals.

By carefully managing the ink’s chemistry, the researchers created circuits that are both functional and versatile—potentially changing the way we design electronics for personal use, medicine, and robotics in the future.