By 2028, NASA intends to land the “first woman and first person of color” on the Moon as part of the Artemis III mission.

This will be the first time humans have been to the lunar surface since the Apollo astronauts last walked there in 1972.

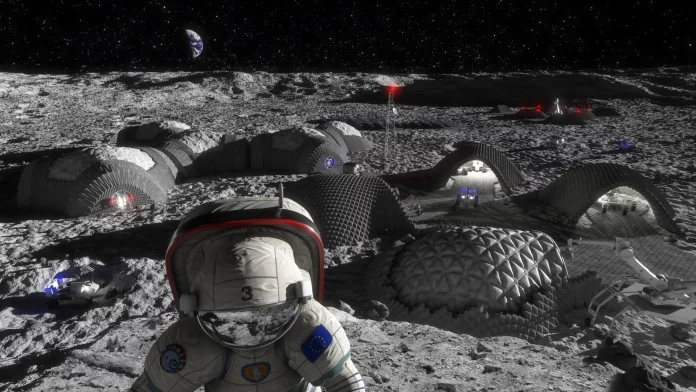

Along with international and commercial partners, NASA hopes that Artemis will enable a “sustained program of lunar exploration and development,” which could include long-term facilities and habitats on the Moon.

Given the expense of launching heavy payloads, sending all the equipment and materials needed to the Moon is impractical.

This means that structures on the Moon must be manufactured using local resources, a process known as in-situ resources (ISRU).

On the Moon, this process leverages advancements in additive manufacturing (AM), or 3D printing, to turn lunar regolith into building materials. Unfortunately, technical issues mean that most 3D printing techniques are not feasible on the lunar surface.

In a recent study, a team of researchers led by the University of Arkansas proposed an alternative method where light-based sintering is used to manufacture lunar bricks, rather than printing while structures.

The research team is led by Wan Shou, an Assistant Professor in the Department of Mechanical Engineering at the University of Arkansas. He is joined by Cole McCallum, Youwen Liang, and Nahid Tushar, an Honors College Fellow, Research Assistant, and Doctoral Student in the University’s College of Engineering.

The team also included researchers from the Department of Mechanical and Aerospace Engineering at the University of Houston and the Faculty of Engineering and Natural Sciences at Tampere University.

As they note in their paper, creating a permanent (or semi-permanent) base on the Moon has been the subject of research studies and proposals since the Apollo Era.

These plans have always been marred by the simple fact that the requisite machinery and construction materials would require many heavy launch vehicles to deliver them at great cost.

While the cost of sending payloads has dropped significantly in the last decade, largely thanks to the commercial space sector’s development of reusable rockets, the cost of launching everything astronauts would need to build a lunar facility is still prohibitive.

As a result, only ISRU will suffice for creating bases on the Moon. Unfortunately, most of the proposed methods for 3D printing structures are not practical in the lunar environment, where the gravity is significantly lower (16.5% that of Earth) and temperatures are extreme.

In the Moon’s South Pole-Aitken Basin, where NASA and other space agencies are planning to build their bases, temperatures range from 54°C (130°F) in the sunlight areas to -246°C (-410°F) in the shadowed regions.

This is because most AM methods require additional supplies to be launched for the Moon, including solvents, polymers, or other bonding agents.

Examples include the European Space Agency’s (ESA) work with architecture firm Foster + Partners to create a 3D-printed moonbase concept. As Prof. Sou explained:

There are many AM methods that require a solvent to prepare paste or composites for extrusion or printing; these approaches are not feasible, as transporting solvents can be very expensive, and the evaporation of solvents can cause many potential issues. Several methods use binders or polymers to realize AM; they have similar issues—shipping additional materials, waste handling. Also, running these machines (i.e., printers) requires energy supplies.

Sintering technology has also been explored as a potential method for 3D printing structures on the Moon. This consists of bombarding regolith with lasers, microwaves, or other energy sources to turn it into a molten ceramic. This ceramic is then printed out, layer by layer, and cools and hardens once exposed to air or the vacuum of the lunar environment. This method is energy-intensive and would likely require a nuclear power source, such as a kilopower reactor.

“Because of this, our team envisions a system where only lunar material is needed for the structures themselves, thus eliminating the bottleneck of binder resupply missions from Earth,” added Cole, who was the first author on the paper describing their findings.

The method they tested and recommend is known as light-based sintering, which relies on sunlight concentrated by a set of optics to bombard and melt lunar regolith into feedstock. Researchers have tested this technology on Earth using lunar regolith simulant to manufacture glass and mirrors. On the Moon, solar energy is consistently present and abundant in sunlit regions, making it much more reliable than a power source that must be transported. The system’s simplicity makes it highly desirable for challenging environments where repairs will be difficult if anything breaks down.

However, experiments have shown that the technology still experiences problems when used to fashion entire structures. To this end, Sou’s team focused on manufacturing building components instead. Said Cole:

While most research on this topic still relies on a mixture of binder and lunar soil, the silica content of regolith is such that at high enough temperatures it can bind to itself when sintered. What we found when attempting this with larger structures was that there was less uniformity and therefore less precision in the parts we created.

From this, we determined that the best use case for our method was to focus on fabricating a large number of interlocking and reconfigurable bricks for use in large-scale structures. We believe this “Lego Bricks” approach is also beneficial because the equipment can fit the volume constraints for lunar missions since the overall space needed to fabricate each unit is much smaller.

Their work builds on existing research into sintering technology that leverages different energy sources to melt lunar regolith and create building materials. This includes NASA’s work with space architectural firm SINTERHAB, which proposed equipping the agency’s All-Terrain Hex-Limbed Extra-Terrestrial Explorer (ATHLETE) vehicle with microwave-sintering technology. However, said Cole, their concept is especially attractive because of the way it produces reconfigurable bricks.

The reconfigurability of our brick assemblies, in particular, is exciting because of the flexibility we can achieve with the building process. Because different parts will have different material requirements, we could see a myriad of techniques being employed depending on the problem being faced. For structures where a bulk of material is needed and where high precision isn’t demanded, as in the case of radiation shielding, we feel our method holds a lot of promise.

Before the concept can be realized, however, much work still needs to be done. As Shou indicates, more research is needed to optimize the sintering parameters and material properties. The team also plans to build a prototype and conduct laboratory tests, which they hope will allow them to refine and scale the technology for use on the Moon. They also need to consider how the resulting 3D printer will transport itself along the lunar surface, what power options it would rely on, and other considerations.

“When it comes to full implementation, there’s a lot of engineering that still needs to be done,” Cole concluded. “In the future, we’ll need to consider how the sintering process changes in a vacuum, or what modifications to the build platform will be needed so that parts can be reliably made while tracking the sun, for example.

In addition, our device needs to be able to withstand harsh conditions compared to the lab environment we worked in for this research. These are all challenging problems, but in the end, the science behind all of this is well understood.”

Written by Matthew Williams/Universe Today.