Scientists have discovered a rare and powerful crystal hidden inside a 3D-printed aluminum alloy.

This unusual crystal, called a quasicrystal, helps make the metal much stronger—and it was found by surprise.

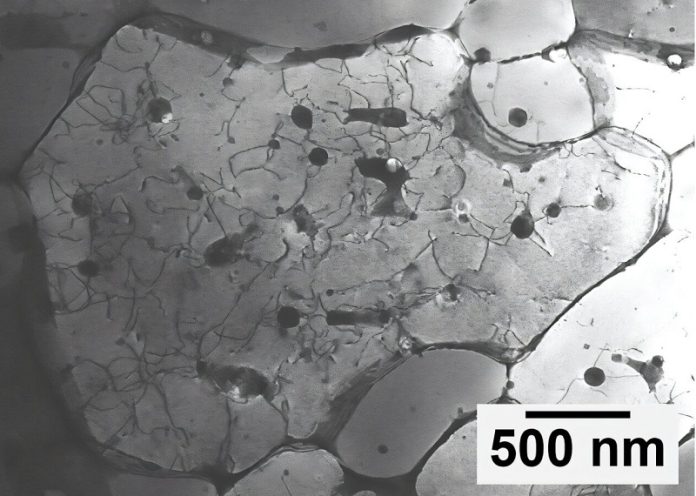

Andrew Iams, a materials engineer at the U.S. National Institute of Standards and Technology (NIST), spotted the quasicrystal while studying the metal with an electron microscope.

He was examining a new aluminum-zirconium alloy, looking for the secret to its strength.

What he saw made him pause—he noticed the atoms were arranged in a very odd and unfamiliar pattern.

That’s when Iams realized he might have found a quasicrystal.

These crystals don’t follow the usual rules of how atoms are arranged in solid materials. Most crystals, like salt, repeat the same pattern over and over again.

Quasicrystals, however, create complex patterns that never exactly repeat, even though they completely fill the space.

To be sure it was a quasicrystal, Iams had to rotate the crystal and examine it from different angles. He confirmed it had fivefold, threefold, and twofold rotational symmetry—something no ordinary crystal has. These shapes match the form of a 20-sided figure called an icosahedron.

Interestingly, quasicrystals were first discovered at NIST back in the 1980s by Dan Shechtman, who later won a Nobel Prize for his work. Now, decades later, another NIST scientist has found new quasicrystals—this time in a 3D-printed metal.

This matters because 3D metal printing, also known as powder bed fusion, is changing how we build things like airplane parts, car frames, and heat exchangers. In this method, layers of fine metal powder are melted with a laser to create complex shapes. The problem is that strong aluminum alloys usually don’t work well with this process—they crack too easily.

But in 2017, scientists discovered a way to add zirconium to aluminum powder, which made it printable without cracks.

Now, the NIST team has shown that part of the alloy’s strength comes from the quasicrystals that form during the printing process. These special crystals disrupt the usual atomic patterns, making it harder for atoms to slip past each other. That’s what gives the metal its strength.

Physicist Fan Zhang, who co-authored the study, believes this discovery will lead to better alloy design. Now that scientists know quasicrystals can improve strength, they might try to create them on purpose in future metals. This could lead to lighter, stronger parts for planes, cars, and much more—thanks to a strange and beautiful crystal.

Source: KSR.