Radioactive materials play a crucial role in treating cancer, often used in hospitals to target and destroy harmful cells.

But getting these powerful substances from where they’re made to where they’re needed is a delicate and risky process.

If intercepted, radioactive materials could be misused, posing a serious threat to public safety.

That’s why researchers at the U.S. Department of Energy’s Oak Ridge National Laboratory (ORNL) are developing smarter, more secure ways to track and protect radioactive shipments.

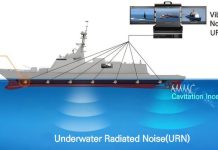

The main problem with shipping radioactive material is tracking it throughout the journey.

Right now, tracking systems work like regular mail: once a package is delivered, tracking stops.

But in the case of radioactive materials, it’s vital to know exactly where the package is at all times—especially if it changes hands multiple times before reaching its destination.

To solve this, ORNL researchers are working on a project called SPaCES (Smart Packaging for Critical Energy Shipments).

They’re using advanced technology, including 3D printing, to build “smart” containers that include sensors and electronics built right into the package itself.

These smart systems can monitor the shipment from the moment the material is placed inside the container until it’s removed for use at a medical facility. This could help prevent tampering, theft, or loss during transit.

Ph.D. researcher Mingyan Li and her team are collaborating with experts in nuclear packaging and advanced manufacturing to make sure these smart containers are not only secure but also strong enough to meet national safety standards.

The materials used for the containers are being tested to ensure they can handle real-world situations—being dropped, crushed, or even attacked.

One of the unique features of this project is the use of sensors that alert authorities if the package is tampered with. These sensors are supported by a secure cloud-based tracking system developed at ORNL called T-STAR. This system only shares location data with people who need to know, reducing the risk of hackers or bad actors tracking the shipment.

In addition to better tracking, the researchers are also exploring robotics to reduce the risk of radiation exposure for workers, and using data analysis to build stronger, more effective containers.

For the ORNL team, this project is about more than just safety—it’s also about national security. With around 3 million shipments of hazardous materials every year, strengthening the security of each one can have a big impact.

Researcher Mingyan Li says, “It’s exciting to see our ideas come to life and help protect people across the country.”