Stanford University researchers have created a new super-thin material that conducts electricity better than copper when made just a few atoms thick.

This discovery could lead to faster, more energy-efficient electronics in the future.

As computer chips get smaller and more advanced, the tiny metal wires inside them – usually made of copper – are struggling to keep up.

When these copper wires become too thin, they lose their ability to carry electricity efficiently and waste more energy as heat.

This has become a big problem for making smaller, more powerful electronics.

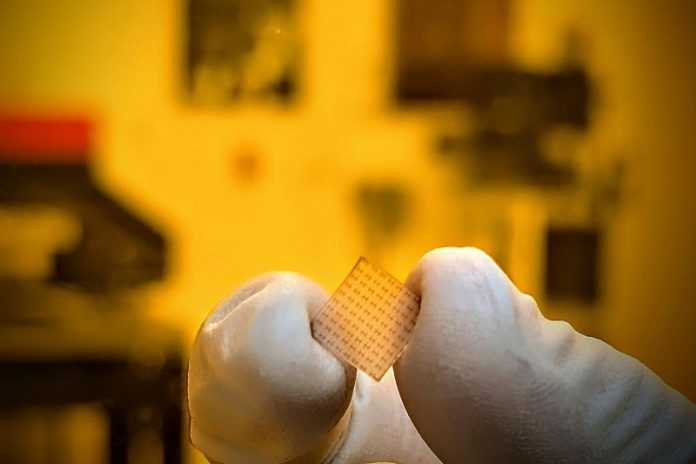

In a recent study published in Science, Stanford engineers showed that a material called niobium phosphide can outperform copper at extremely small thicknesses, below 5 nanometers.

That’s about 10,000 times thinner than a human hair. Even better, this new material can be made at lower temperatures, which makes it easier to use in modern chip-making processes without damaging other parts.

Niobium phosphide belongs to a special group of materials called topological semimetals. These materials are unique because their surfaces conduct electricity better than their insides.

So, when a film of niobium phosphide becomes thinner, the surfaces make up more of the material and actually help it conduct electricity even better. In contrast, copper performs worse when it gets thinner.

Dr. Asir Intisar Khan, the lead author of the study, said, “We are overcoming a major limitation of traditional materials like copper. Our new conductor allows faster and more efficient electrical signals through ultra-thin wires, which could save a lot of energy—especially in large data centers.”

What makes this breakthrough even more exciting is that the niobium phosphide used in the study was not in a perfect crystal form. Usually, materials that conduct electricity very well need to be grown in perfect, single-crystal structures, which require high temperatures. But the Stanford team managed to create these films in a non-crystalline form at just 400°C, which is low enough for safe chip manufacturing.

“This opens the door to real-world use,” said Professor Yuri Suzuki, one of the co-authors. “You don’t need perfect crystals. Even slightly messy structures can work well.”

While copper will still be used in thicker parts of chips, niobium phosphide could be used in the tiniest, most delicate areas. The research team is now studying other similar materials to see if they can do even better.

Professor Eric Pop, who led the research, summed it up: “This new material may help solve power and energy problems in today’s and tomorrow’s electronics.”