Imagine a robot that walks right out of a 3D printer—no wires, no electronics, no batteries—just a puff of air to get it moving.

That’s exactly what researchers at the University of California San Diego have created.

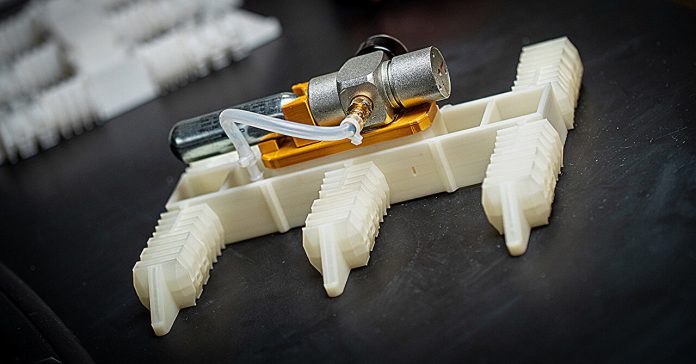

These robots are made from a single material, printed in one piece using an ordinary 3D printer.

All it takes to get them going is a small cartridge of compressed gas.

Once connected, the robot starts walking—no assembly or extra parts needed. Even more impressive, each robot costs only about $20 to make.

“This is a totally new way to think about building robots,” said Professor Michael Tolley from the university’s Department of Mechanical and Aerospace Engineering.

Because they don’t use electronics, these robots can be useful in places where normal electronics wouldn’t work—like in areas with high radiation, after a disaster, or even in space.

The team showed that as long as the robots stay connected to a source of air pressure, they can keep moving for up to three days. They’ve also been tested walking on different surfaces such as sand and grass—and even underwater.

Instead of using traditional hard parts like motors and wires, the entire robot is made from soft plastic material. One of the hardest parts of the project was designing and printing everything—legs, artificial muscles, and a control system—all in one go using the same soft material.

The team, led by postdoctoral researcher Yichen Zhai, came up with a clever solution. They created a soft, air-powered control system—similar to how old steam engines worked. This pneumatic system pushes air through a circuit that controls the robot’s six legs. The legs move up, down, forward, and backward, allowing the robot to walk in a straight line.

The next step for the team is to figure out how to store the compressed gas inside the robot itself. They also want to explore using eco-friendly materials, like ones that can be recycled or biodegraded.

In the future, the team hopes to add features like grippers or other tools, making the robots even more useful.

This exciting project was done in collaboration with BASF’s California Research Alliance, where they tested different materials to find the best ones for 3D printing.

With more development, these simple, soft robots could be ready to explore environments too harsh for people—or even other machines.

Source: UC San Diego.