Researchers at RMIT University have developed a groundbreaking new material inspired by the skeleton of a deep-sea sponge.

This innovative lattice structure offers exceptional strength, stiffness, and impact resistance, making it a promising option for construction, protective gear, and medical applications.

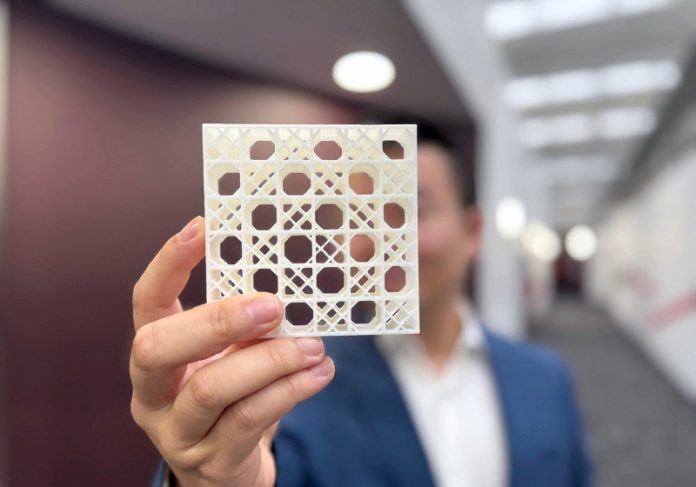

The design takes inspiration from the Venus’ flower basket, a deep-sea sponge with an intricate, lattice-like skeleton.

By mimicking this natural structure, researchers have created a double lattice material that outperforms traditional auxetic materials—those that expand when stretched and contract when compressed.

Dr. Jiaming Ma, lead author of the study, explained that while most materials become thinner when stretched or wider when compressed, auxetic materials do the opposite.

This unique property allows them to absorb and distribute impact energy more effectively, making them valuable in various applications.

What makes this lattice special?

Traditional auxetic materials often lack stiffness and energy absorption, limiting their practical use. However, the new double lattice design overcomes these challenges:

- It is 13 times stiffer than existing auxetic materials.

- It absorbs 10% more energy than conventional designs.

- It maintains its auxetic properties over a 60% greater strain range than current materials.

According to Dr. Ngoc San Ha, this breakthrough opens up many possibilities for next-generation sustainable building materials. The lattice could be used in construction to reduce the amount of steel and concrete needed while maintaining structural strength.

This bioinspired lattice structure could be used in:

- Buildings – Steel frames using this design could reduce construction materials and costs.

- Protective Gear – Lighter and stronger bulletproof vests and sports equipment.

- Medical Implants – Improved materials for prosthetics and stents.

- Earthquake-Resistant Structures – The material’s ability to absorb energy could help dampen vibrations during seismic activity.

The team has successfully tested the design using computer simulations and 3D-printed samples made from thermoplastic polyurethane. Their next goal is to produce steel versions to integrate with concrete and rammed earth structures for real-world construction.

They also plan to explore how machine learning can optimize the design further, potentially leading to programmable materials that adjust to different conditions.

Honorary Professor Mike Xie emphasized the value of looking to nature for engineering solutions. “Millions of years of evolution have optimized these structures. By learning from them, we can create smarter, stronger, and more efficient materials.”

With this exciting innovation, the future of construction and safety equipment could become lighter, stronger, and more sustainable.

Source: RMIT University.