Scientists have discovered a way to make 3D printing faster and more precise using holograms.

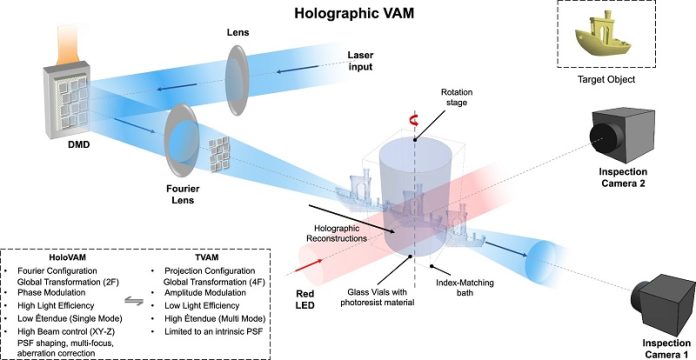

Traditional 3D printers build objects layer by layer, but a newer technique called tomographic volumetric additive manufacturing (TVAM) uses laser light to solidify liquid resin into a shape.

TVAM can print objects in seconds instead of minutes, but it has a major downside: only about 1% of the laser light is actually used to create the object, making it very inefficient.

Researchers from EPFL’s Laboratory of Applied Photonic Devices, led by Professor Christophe Moser, and the SDU Centre for Photonics Engineering, led by Professor Jesper Glückstad, have developed a new TVAM method that significantly reduces energy use while increasing resolution.

Their findings were recently published in Nature Communications.

Instead of simply shining laser light on the resin, the team projects a 3D hologram of the shape they want to create.

This method takes advantage of the phase (position) of light waves instead of just their amplitude (height).

As a result, more of the laser’s energy is effectively used, improving both efficiency and accuracy.

“All pixel inputs contribute to the holographic image at all depths, making the process more efficient and allowing us to control the projection depth better,” explains Moser.

The researchers successfully printed tiny 3D objects such as boats, spheres, cylinders, and artworks in under 60 seconds. Their new approach requires 25 times less optical power than earlier methods, making it a breakthrough in energy-efficient printing.

The holograms are created using a technique called HoloTile, invented by Professor Glückstad. This method eliminates unwanted speckle noise, which can make images look grainy.

Although other studies have explored holographic 3D printing, the EPFL-SDU team’s approach is the first to achieve such high-quality results.

Maria Isabel Alvarez-Castaño, a lead researcher on the project, highlights another advantage: holographic beams can be “self-healing,” meaning they continue to function even when small particles are present in the resin.

This feature makes the method ideal for biomedical applications, where scientists print with bio-resins and hydrogels containing living cells.

“We want to use this method to create 3D biological structures, such as life-size models of tissues and organs,” says Alvarez-Castaño.

Looking ahead, the team aims to double the efficiency of their method. Moser hopes that with further advancements, they will be able to print objects simply by projecting a hologram onto a resin, eliminating the need for rotation. This would make the process even faster and more scalable.

Another advantage is that the holograms can be coded using standard commercial equipment, making this method practical for a wide range of uses.

“Holographic TVAM technology paves the way for the next generation of fast, accurate, and energy-efficient 3D printing systems,” Moser concludes.